Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What ratio is a 14 degree dovetail?

This 14° marker equates to a ratio of 1:4. When used with thinner stock, the 14° angle results in a better looking joint. This different angle also gives you a slightly stronger dovetail interlock on the thinner material.

What size dovetail should I use?

Your tails should be around 18mm > 35mm for fine work like drawers and 35mm > 55mm on larger work like a chest.

What is the most common dovetail angle?

Percy Blandford, who has been writing about woodworking for a long time, writes in “The Woodworker’s Bible” that any angle between 7.5° and 10° is acceptable. The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods.

What is a standard dovetail?

Standard Size Dovetails. A standard size dovetail is as tall as your lumber is thick. This assumes you are joining boards of the same thickness with through-dovetails and that you intend to have them flush with the finished corner surfaces on both legs of the corner.

What is the common dovetail ratio?

With regard to what to use, a common recommendation is 1:8 for hardwoods and 1:6 for softwoods. These recommendations are based on some arguments related to strength. However, people use a lot of different ratios depending on application and aesthetics.

What is 1 to 6 ratio dovetail?

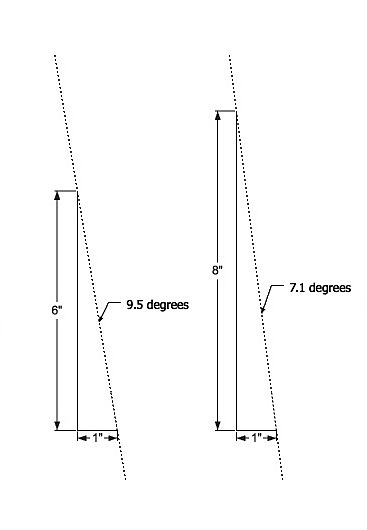

A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle. A 1:8 ratio – one unit horizontal with eight matching units drawn vertical – is an angle of 7.1 degrees.

Is 11mm dovetail the same as 3 8?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

What makes a dovetail joint so strong?

Methods. The dovetail joint is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

What are the weaknesses of dovetail?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

How deep should a dovetail joint be?

Typically we use 1 ½” – 2” deep dovetails that are about 2” less deep than the joist, and 4” less deep than the girt – but that is just a starting point – the loads and reactions have to be calculated from there.

What is English dovetail?

English dovetails are the most common. They have interlocking joints and allow the most amount of space – usually several more inches of room than you would get with French dovetails. This is because the dovetail groove cannot be put all the way at the edge of a drawer with French dovetails.

Is 3 8 the same as 11 mm?

10mm = just over 3/8 inch. 11mm = almost 7/16 inch. 12mm = almost 15/32 inch (= almost 1/2 inch) 13mm = just over 1/2 inch.

What is the best wood for dovetails?

Try a few in pine, but if you want to have useful practice you need to be using hardwoods. That is because pine compresses easily so is both forgiving and frustrating. To keep the cost down you could try poplar? Not a true hardwood but much harder than pine.

What is the formula for measuring dovetails?

To obtain dimension x for measuring male dovetails, add 1 to the cotangent of one-half the dovetail angle α, multiply by diameter D of the rods used, and add the product to dimension α.

What is the ratio of oak dovetails?

My take on dovetail angles might appear to be strange, but I have solid reasons for my choice , if I do say so myself. Here goes. Dovetail angles are most notably described in degrees, but is often stated as a ratio, either 1:8 or 1:6.

What is the angle of a standard dovetail cutter?

Many times, small articles are cut 60 or 45 degree dovetails for simplicity’s sake becuase they are a stock cutter angle even though another angle might be a better choice for the service.

What degree is a dovetail bit?

The first dovetail jigs were limited to evenly spaced, half-blind dovetails with equally sized pins and tails. Many of these early jigs were designed to work with a 14° bit. This steeper angle certainly makes for a strong joint.

How thick should a dovetail jig be?

Dovetail Jig rave about the user-friendly features. The jig’s patented alignment lines and router bit-depth stop simplify set up and get you up and running in no time. This versatile jig accepts stock from 1/4 to 1-1/8 inch in thickness and up to 12 inches in width.

What is the angle of a 7 1 dovetail?

My go-to angle for through dovetails in most hardwoods is 7:1 (8.1°), such as for a carcase or box in cherry, maple, or walnut with stock thickness of 9/16″-13/16″. It has enough angle to form a strong mechanical lock but not too much to produce fragile tail corners or overly fussy fitting.

What is the spacing for dovetails?

What rifles have 11mm dovetail?

Will 3 8 dovetail fit picatinny rail?

3/8 Dovetail to Picatinny Adapter Rail -Short adaptor Rail attaches to 3/8 Dovetail rails and converts it to Picatinny Rail for mounting Red Dot optics with Weaver/Picatinny type rings and mounts.

What is a 3 8 dovetail?

3/8″ dovetail rails, sometimes call tip off rails, consist of two thin parallel grooves and are used almost exclusively on rimfire rifles and air rifles. 3/8″ dovetail rails are a common, standardized style within the rimfire industry and are inexpensive to machine into the firearm’s frame.

What is stronger dovetail or finger joint?

Although the finger joint is not mechanically interlocking like a dovetail, the joint is amazingly strong. Today’s modern adhesives and the large glue surface make the finger joint equally as strong as the dovetail throughout the life of the adhesive.