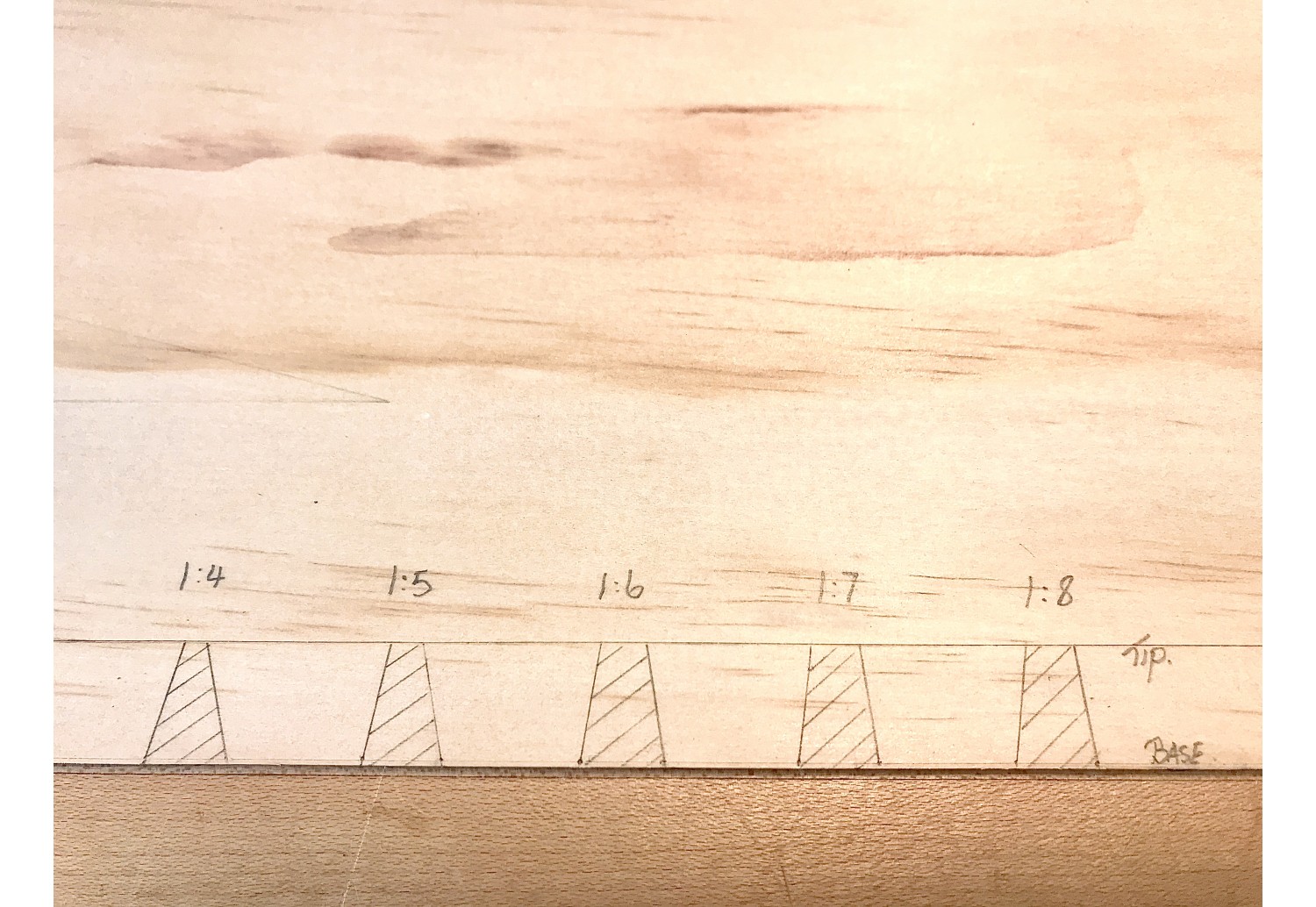

A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle. A 1:8 ratio – one unit horizontal with eight matching units drawn vertical – is an angle of 7.1 degrees.The left-hand photo shows the “ratio” method to layout the angle of your dovetails. (I used SketchUp to draw and show the angles.) A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle.

What is the best ratio for dovetails?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What ratio is a 14 degree dovetail?

Commonly accepted ratios are 1:8 for hardwoods and 1:6 for softer timber. This 14° marker equates to a ratio of 1:4. When used with thinner stock, the 14° angle results in a better looking joint.

What ratio for dovetail hardwood?

Anything from 1:6 to 1:9 looks good and works well. Too little rise leaves corners with short grain that easily breaks off, too much rise looks like a poorly made box joint. As long as it looks good, and assembles without breaking, its a good joint.

What is the best ratio for dovetails?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What ratio for dovetail hardwood?

Anything from 1:6 to 1:9 looks good and works well. Too little rise leaves corners with short grain that easily breaks off, too much rise looks like a poorly made box joint. As long as it looks good, and assembles without breaking, its a good joint.

What is the most popular dovetail joint?

Single-lap Dovetail The single-lap (known to many folks as a half-blind dovetail) is the best known of the dovetails since it’s used to join the front to the sides of a drawer.

What are common dovetail sizes?

What is the angle of a 6 1 ratio?

A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle.

What is the most common dovetail angle?

Percy Blandford, who has been writing about woodworking for a long time, writes in “The Woodworker’s Bible” that any angle between 7.5° and 10° is acceptable. The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods.

What is a standard dovetail?

A series of pins cut to extend from the end of one board interlock with a series of ‘tails’ cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

What is the minimum thickness for a dovetail?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

Is 11mm dovetail the same as 3 8?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

What is the ratio of tail to pin in a dovetail joint?

The line between that end point and starting point will be the angle of your tail and pin sides. 6:1 (9.5°) and 8:1 (7.1°) dovetail ratios are the most common (though you’ll often see 4:1 and 10:1 as well).

What are the rules for dovetails?

What is the formula for measuring dovetails?

To obtain dimension x for measuring male dovetails, add 1 to the cotangent of one-half the dovetail angle α, multiply by diameter D of the rods used, and add the product to dimension α.

What makes a dovetail joint so strong?

The dovetail joint is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

What is the best ratio for dovetails?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What ratio for dovetail hardwood?

Anything from 1:6 to 1:9 looks good and works well. Too little rise leaves corners with short grain that easily breaks off, too much rise looks like a poorly made box joint. As long as it looks good, and assembles without breaking, its a good joint.

What is the weakness of dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

Should you glue dovetail joints?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

What is an English dovetail joint?

A dovetail joint is a locking joint. The English dovetail construction tends to allow for the largest possible drawer storage capacity. French dovetail construction is used for more elaborate features such a curved, bowed design.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

What are the rules for dovetail joints?

The general rule is that they measure half the thickness of timber plus around 1 mm along the shoulder line. So these two awl dots are 7 mm in from each edge. These two dots, which mark the corners of the half pins, are now converted into a 1:8 slope at each side.

What size chisels for dovetails?

After years of dovetailing, I noticed that two of my chisels were seeing almost all the action: the 1/4″-wide and a 3/4″-wide tools. I use the narrow one for removing waste between the tails and the larger one for removing waste between pins.

How to find the ratio?

Ratios compare two numbers, usually by dividing them. If you are comparing one data point (A) to another data point (B), your formula would be A/B. This means you are dividing information A by information B. For example, if A is five and B is 10, your ratio will be 5/10.