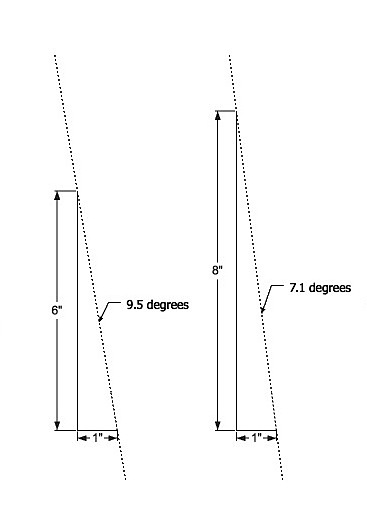

A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle. A 1:8 ratio – one unit horizontal with eight matching units drawn vertical – is an angle of 7.1 degrees.

What dovetail ratio is best?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What ratio is a 14 degree dovetail?

This 14° marker equates to a ratio of 1:4. When used with thinner stock, the 14° angle results in a better looking joint. This different angle also gives you a slightly stronger dovetail interlock on the thinner material.

What are common dovetail sizes?

Dovetails come in several different types and sizes depending on manufacturer, but the most common are the 11 mm and 3⁄8 inch (9.5 mm). Some other less known, but currently commercially available dovetail mounts, are 12, 13, 13.5, 14, 14.5, 16, 16.5, 17 and 19 mm.

What is the formula for measuring dovetails?

To obtain dimension x for measuring male dovetails, add 1 to the cotangent of one-half the dovetail angle α, multiply by diameter D of the rods used, and add the product to dimension α.

What is the common dovetail ratio?

Anything from 1:6 to 1:9 looks good and works well. Too little rise leaves corners with short grain that easily breaks off, too much rise looks like a poorly made box joint. As long as it looks good, and assembles without breaking, its a good joint.

Is 11mm dovetail the same as 3 8?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

What is a 1 to 6 ratio in degrees?

A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle.

What is the most common dovetail angle?

Percy Blandford, who has been writing about woodworking for a long time, writes in “The Woodworker’s Bible” that any angle between 7.5° and 10° is acceptable. The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods.

What degree is a 1 8 dovetail in degrees?

It would be extremely difficult to be able to pick these differences up in your dovetails on a piece of furniture by eye. So in closing your 1:4 Saddle-Tail is for all practical purposes 14 degrees, the 1:6 is close to 10 degrees and the 1:8 is about 7 degrees.

What is a standard dovetail?

The dovetail joint drawers are typically used to link the edges of a drawer to the front and are known for their tensile strength to being pushed apart. Pins or tongues cut from one board’s end interlock with the groove or tail on the other board’s end.

What is the most popular dovetail joint?

Single-lap Dovetail The single-lap (known to many folks as a half-blind dovetail) is the best known of the dovetails since it’s used to join the front to the sides of a drawer.

How thick should dovetails be?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

What are the rules for dovetail design?

As a rule of thumb the dovetail’s maximum width should occupy approximately 1/ 2 to 3/ 4 of the gasket’s width (leaving a 1/ 4 – 1/ 8 of gasket width on each side). For larger gasket widths, multiple dovetails can be made side-by- side, facing the same direction or inverted.

What is half of a dovetail joint?

A half-blind dovetail enables the woodworker to hide the joint from the front end. The tails are housed in sockets in the ends of the board that is to be the front of the item so that their ends cannot be seen. Half-blind dovetails are commonly used to fasten drawer fronts to drawer sides.

What angle are dovetails cut at?

The angle of a dovetail joint should be between 7 and 15 degrees: too broad and the joint won’t be strong enough, too skinny, and the pin can snap.

What is the most popular dovetail joint?

Single-lap Dovetail The single-lap (known to many folks as a half-blind dovetail) is the best known of the dovetails since it’s used to join the front to the sides of a drawer.

What is a standard dovetail?

The dovetail joint drawers are typically used to link the edges of a drawer to the front and are known for their tensile strength to being pushed apart. Pins or tongues cut from one board’s end interlock with the groove or tail on the other board’s end.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

How deep should a dovetail joint be?

so with our current scenario of 3″ we would have 2 x 3/16″ = 3/8″ plus the full pin of 3/8″ so 3/4″ pin accumulation. This then leaves 2 1/4″ for two tails so 1 1/8″ dovetails. As I said, for me, generally, I simply use 3/8″ equally for all of my pins as my standard size in my more general work.

What is a 3 8 dovetail?

3/8″ dovetail rails, sometimes call tip off rails, consist of two thin parallel grooves and are used almost exclusively on rimfire rifles and air rifles. 3/8″ dovetail rails are a common, standardized style within the rimfire industry and are inexpensive to machine into the firearm’s frame.

How many pins are in a dovetail joint?

There is usually a three pin setup but more or less pins can be used depending on how much strength and aesthetics you want.

How do you explain 1 6 ratio?

A ratio is used to describe how two quantities are related. For example, we might say that orange squash is to be mixed with water in a ratio of 1:6. This means that for every 1 part squash, there will need to be 6 parts of water. If there was 100ml of squash, there would be 600ml of water.

What percent is 1 6 ratio?

Answer: 1 out of 6 is 16.67%.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

What is the standard angle for a metal dovetail?

Angles used on dovetails On large industrial scale machines the angle is usually 45º. For smaller dovetails the usual angle is 60º. Any less than this, i.e. 60° on a small machine, complicates the design of the adjustment mechanism. The angle produced is set by the dovetail cutter used.