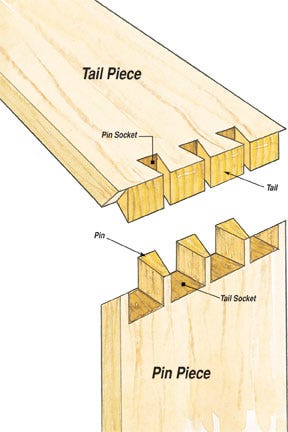

This joint type has two parts, called pins and tails. You can tell the difference between these two pieces because the tails are flared triangular shapes, while the pins are thinner. The tails, which look like those of a dove, are what give the dovetail joint its name.The different types and variations of dovetail joints include:

Dovetail lap joints: A half-lap joint cut in the shape of a dovetail.

Half-Blind dovetails: In these, the pins and tails are hidden. …

Sliding dovetails: Also known as “French dovetails,” these are essentially dado joints cut as a dovetail. …

Mitered dovetails: These join two boards at a right angle, with the material cut to 45 degrees. …

What do dovetail joints look like?

There are two parts to a dovetail joint, pins and tails. The tails look like the tail of a dove (hence the name), and the pins are on the opposite board and fit in between the tails to create a joint that is impossible to pull apart in at least one direction.

How do you date dovetail joints?

When tails and pins of a hand cut dovetail joint are different sizes with large tails (Figs. 3 & 5), it generally means the joint was made before 1860. After 1860, machines began to be used to cut drawer joints and the machine cut pins and tails are virtually always the same size (Fig. 4 & 6).

Where would you see a dovetail joint?

Noted for its resistance to being pulled apart, also known as tensile strength, the dovetail joint is commonly used to join the sides of a drawer to the front. A series of pins cut to extend from the end of one board interlock with a series of ‘tails’ cut into the end of another board.

Do dovetail joints need to be glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

How old are dovetail joints on furniture?

17th Century Dovetails While dovetail joints can be found on ancient Egyptian coffins from 3000 BC, they were not used in European and American furniture until the mid 1600s.

When did they stop using dovetail?

Hand-cut dovetailing was the default until 1860 when uniform machine-cut joints were introduced. But fine cabinetmakers persisted in fitting their joints by hand until the early 1900s, and cabinetmakers in Europe cut dovetails by hand well into the 1930s.

What is an English dovetail joint?

English Dovetail / Through Dovetail The craftsperson usually orients the tails and pins in this joint horizontally, although this isn’t a cardinal rule. It is sometimes called a through dovetail because both the pins and tails go all the way through each-other.

What is an example of a dovetail?

You can also use the word dovetail to show how other things fit well together — like how your picnic plans nicely dovetail with the sunny forecast. A well-made dovetail is a beautiful thing, with wooden projections that slide into notches perfectly, the two sides forming a corner.

Are dovetail joints worth it?

Making sure that you pick a drawer joint that can withstand this type of wear and tear is crucial to the longevity of your kitchen cabinets. Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

Are dovetail joints still used?

Dovetail joints used to be the best way to join pieces of wood, especially a box or drawer. I used to cut them by hand but now you can buy jigs. Modern glues, like Gorilla Glue, are so strong I rarely use a dovetail joint unless it’s going to show. I usually use a rabbet, or sometimes even a butt joint.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint. Glue may be applied to the mating surfaces.

Are dovetail joints worth it?

Making sure that you pick a drawer joint that can withstand this type of wear and tear is crucial to the longevity of your kitchen cabinets. Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

What is the most common dovetail angle?

Lower (7° to 9°) angles are often advised for joining hardwoods, while higher angles (10° to 14°) are recommended for softwoods and even higher angles (14° to 18°) for half-blind dovetails.

Is a finger joint stronger than a dovetail joint?

For box joint, some people put a lot more fingers than it is possible to do with Dovetail. In this case, the gluing surface is larger, and the joint is likely stronger. Also, some find a way to hide a finish nail in the joint. Dovetail has the advantage of a mechanical lock independent of the glue.

Do you clamp dovetail joints?

No need for clamps if you dovetails are tight. I will clamp a board that may have bow a little. Don’t sweat the glue bond, a good dovetail doesn’t depend on glue for much of it’s strength. I bang them together with a rubber mallet.

Can you make a dovetail joint by hand?

Of the four types of dovetail joints (through dovetail, half blind dovetail, secret mitered dovetail, and the sliding dovetail), the through dovetail is the most basic method, and a perfect one for hand cutting. Contrary to what seems to be popular belief on the internet, they are not really all that hard.

Are dovetail joints difficult?

Hand-cutting a dovetail joint is kind of a woodworking high-wire act; one slip of the saw or chisel and the joint either won’t fit together or will look sloppy. It takes a lot of time to master the ability to cut dovetails quickly and well (by hand or machine), without a lot of fussing around.

How can you tell if furniture is vintage?

A few signs that furniture is newer include consistent color, lack of patina, machine-cut moldings/carvings, and modern screws or nails. Things like mortise-and-tenon joints, wood pegs, hand-cut dovetails, and rose head nails are typically found in antique furniture.

How can you tell the year of furniture?

Stamps, Labels or Maker’s Marks These marks will be able to tell you who made the furniture, where it was manufactured and often the year that it was made.

What is the difference between English dovetail and French dovetail?

English dovetails are the most common. They have interlocking joints and allow the most amount of space – usually several more inches of room than you would get with French dovetails. This is because the dovetail groove cannot be put all the way at the edge of a drawer with French dovetails.

Are dovetail joints permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

What is a French dovetail joint?

Fyi, the English dovetail technique is also commonly referred to as a butt joint. French Dovetail: This technique is based on cutting out a slat in the middle of a board and also a corresponding piece of wood that can slide into the middle cutout. English and French Dovetail Drawer Construction.

What is the angle of a dovetail joint?

The angle of a dovetail joint should be between 7 and 15 degrees: too broad and the joint won’t be strong enough, too skinny, and the pin can snap. So the angle of the dovetail mainly depends on the use and wear the joint will get. 5. They are called ‘dovetails’ because they are shaped like the tail feathers of a dove!

What is the strongest joint in woodworking?

Mortise and tenon joints have stood the test of time for their remarkable strength. This traditional joint involves a projecting piece of wood, called a tenon, securely fitting into a corresponding cavity, a mortise. It can be reinforced with glue or wedges for stability for a stronger hold.

What is a standard dovetail?

Standard Size Dovetails. A standard size dovetail is as tall as your lumber is thick. This assumes you are joining boards of the same thickness with through-dovetails and that you intend to have them flush with the finished corner surfaces on both legs of the corner.