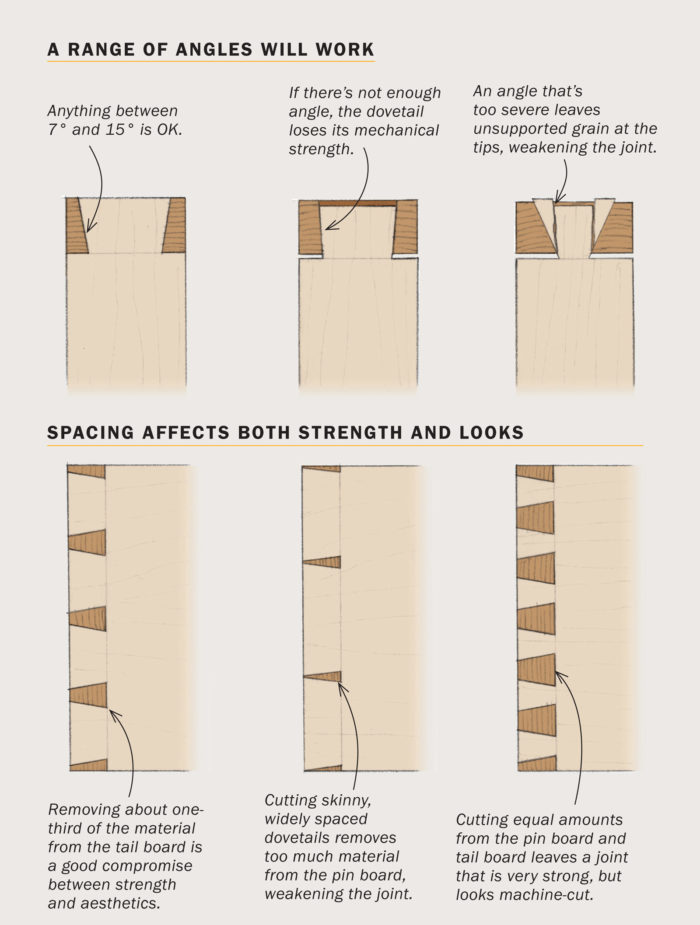

Lower (7° to 9°) angles are often advised for joining hardwoods, while higher angles (10° to 14°) are recommended for softwoods and even higher angles (14° to 18°) for half-blind dovetails.

What is the angle of a traditional dovetail?

There are different types of dovetail joints. The angle of slope varies according to the wood used, purpose of joint and type of work. Typically the slope is 1:6 for softwoods, and a shallower 1:8 slope for hardwoods. Often a slope of 1:7 is used as a compromise.

What ratio is a 14 degree dovetail?

So in closing your 1:4 Saddle-Tail is for all practical purposes 14 degrees, the 1:6 is close to 10 degrees and the 1:8 is about 7 degrees.

What is the standard dovetail ratio?

6:1 (9.5°) and 8:1 (7.1°) dovetail ratios are the most common (though you’ll often see 4:1 and 10:1 as well). 8:1 and higher ratios have a steeper angle that works well in hardwoods, since these woods aren’t as likely to compress and don’t require as extreme of wedge.

What angle is 6 to 1 dovetail?

A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle. A 1:8 ratio – one unit horizontal with eight matching units drawn vertical – is an angle of 7.1 degrees.

What is the difference between English dovetail and French dovetail?

English dovetails are the most common. They have interlocking joints and allow the most amount of space – usually several more inches of room than you would get with French dovetails. This is because the dovetail groove cannot be put all the way at the edge of a drawer with French dovetails.

What size dovetail should I use?

For drawers, boxes or trays 2″ or less I generally like a single dovetail. For 3″ to 3 1/2″ and less two dovetails, for 4″ three dovetails, for 5″ to 6″ four dovetails and for 6″ four or possibly five.

How deep should a dovetail joint be?

Two-step Shouldered Joints With a 3⁄4″-diameter flush-trimming bit in your router, plow out the dado to 3⁄16″ deep. Next, take your router with a tem- plate guide and dovetail bit, set it to 9⁄16″ deep (without moving the straightedge) and make the cut into the case side.

What angle is a hand cut dovetail?

When creating original work, it’s best to keep the angle ratio between 1:8 (7°) and 1:6 (9.5°). If the tail angles are too shallow, you’ll lose the classic dovetail look (not to mention holding power). And if they’re cut too steep, they’ll appear exaggerated and be prone to chipping.

What angle should a sliding dovetail be?

Sliding Dovetails Require Great Precision The different here is setting the 12 degree angle for the walls of the pin. I use a sawing fence with a 12 degree angle on one edge and it makes the sawing really simple. Just keep the saw plate pressed firmly against the fence and voila! You get perfect sliding dovetail pins.

Is 11mm dovetail the same as 3 8?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

What are the proportions for a dovetail joint?

The only consistent advice I find is keep dovetail length about equal to board thickness. And keep dovetail ratios between 1:6 and 1:8.

How do you find the dovetail angle?

Unless its a miniature dovetail, it should be easy to blue the ends, transfer on some paper, extend the lines and use a simple protractor. Usually the angles are 45, 55, 60 degrees etc.

Is dovetail 11mm?

The standard 22 tip-off dovetail in the US is 3/8″ at the bottom and up to 1/2″ at the top. The European 11mm dovetail is typically 11mm at the top and perhaps 8mm at the bottom. The 11mm dovetail typically has a 60 degree angle from the bottom inside corner to the top where the 3/8″ is typically 45 degrees.

What angle is a 12 to 1 slope?

For every 1 unit of vertical rise, there are 12 units of horizontal run, as in the case of a 1:12 slope. The angle of a slope is the tangent value. Thus, a slope of 1:12 is arc tan (1/12) = 4.763642692 degrees.

What angle is a hand cut dovetail?

When creating original work, it’s best to keep the angle ratio between 1:8 (7°) and 1:6 (9.5°). If the tail angles are too shallow, you’ll lose the classic dovetail look (not to mention holding power). And if they’re cut too steep, they’ll appear exaggerated and be prone to chipping.

What is the angle of a sliding dovetail?

Sliding Dovetails Require Great Precision The different here is setting the 12 degree angle for the walls of the pin. I use a sawing fence with a 12 degree angle on one edge and it makes the sawing really simple. Just keep the saw plate pressed firmly against the fence and voila! You get perfect sliding dovetail pins.

What angle is a dovetail slide?

Angles used on dovetails On large industrial scale machines the angle is usually 45º. For smaller dovetails the usual angle is 60º. Any less than this, i.e. 60° on a small machine, complicates the design of the adjustment mechanism. The angle produced is set by the dovetail cutter used.

What is the geometry of dovetail?

Is dovetail the highest quality?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

What are the weaknesses of dovetail?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

What are the rules for dovetail?

RULES: Dovetail is a better ball stroke play game played with a partner, with each player having their gross score recorded on a minimum of 8 holes. Both partners play the holes individually to the stroke play format and then select which score is entered on the card.

What is stronger dovetail or finger joint?

Frid wrote that finger (or box) joints are stronger than through dovetails because the fingers offer much more glue surface.

Are dovetail joints worth it?

Making sure that you pick a drawer joint that can withstand this type of wear and tear is crucial to the longevity of your kitchen cabinets. Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

Should dovetail joints be glued?

Being a mechanical joint, a dovetail does not rely on glue for strength in drawer box construction. The glue is only needed to keep the joint from sliding apart sideways. To avoid hydraulic problems, I just apply a thin coat of glue to the diagonals of the joint and leave the rest of the joint dry.

What if my dovetail joint is too loose?

When adjusting bit depth, remember “heighten to tighten, lower to loosen.” In other words, if your dovetail joint is too loose, you should increase the bit depth. On the other hand, for a joint that’s too tight, reduce the depth of cut. It might take some trial and error to get the exact setup for a perfect joint.