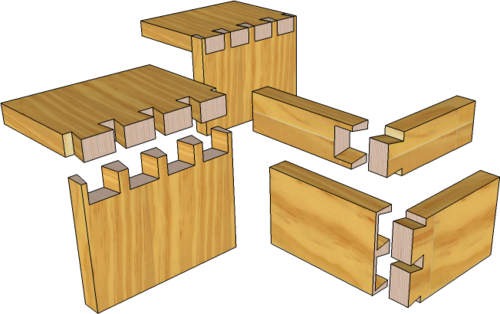

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

What are the disadvantages of a dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

Do dovetail joints need to be glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

Are dovetail joints strong?

Methods. The dovetail joint is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

What is stronger dovetail or finger joint?

Frid wrote that finger (or box) joints are stronger than through dovetails because the fingers offer much more glue surface.

Are dovetail joints worth it?

Making sure that you pick a drawer joint that can withstand this type of wear and tear is crucial to the longevity of your kitchen cabinets. Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

What is the strongest joint in woodworking?

Mortise and tenon joints have stood the test of time for their remarkable strength. This traditional joint involves a projecting piece of wood, called a tenon, securely fitting into a corresponding cavity, a mortise. It can be reinforced with glue or wedges for stability for a stronger hold.

How deep should a dovetail joint be?

Two-step Shouldered Joints With a 3⁄4″-diameter flush-trimming bit in your router, plow out the dado to 3⁄16″ deep. Next, take your router with a tem- plate guide and dovetail bit, set it to 9⁄16″ deep (without moving the straightedge) and make the cut into the case side.

How do you take apart a glued dovetail joint?

Heat the area around the joint with a heat gun. Continue to move the heat gun over the joint and soften the glue holding the joint together. You can purchase a heat gun online or at a hardware store. If you don’t have a heat gun, you can use a hairdryer on the high setting.

When would you use a dovetail joint?

Finally, because the two connected pieces of wood are joined at a 90-degree angle, dovetails are typically used in the construction of corners in drawers, chests, or other box-like containers. However, you do occasionally find them elsewhere, such as on tables, desks, or other casegoods.

What is the weakest joint in carpentry?

The butt joint is the simplest joint. An unreinforced butt joint is also the weakest joint, as it provides a limited surface area for gluing and lacks any mechanical interlocking to resist external forces.

Which is the weakest carpentry joint type?

A butt joint uses a simple technique whereby two pieces of material are joined together at their ends, without any special shaping or cutting. Although it is simple, the butt joint is also the weakest of the wood joinery types.

What is the weakest type of woodworking joint?

A butt joint is the most basic kind of wood joint where the end of one piece of material butts up to another without any shaping done to the material. Because this technique utilizes minimal surface area for glue, it’s generally considered a weak joint unless supported by additional fasteners such as nails and screws.

How much weight can a dovetail hold?

Dovetail Hauling Capacity 4,000 lbs. from center of Dovetail Forward. Dovetail Lift Capacity of 10,000 lbs.

What is the strongest end joint?

MORTISE AND TENON JOINT Mortise and tenon joints are widely regarded as one of the strongest and most reliable woodworking joints. They involve creating a mortise, or a hole, in one piece of wood and a tenon on the end of the other piece, which fits into the mortise.

What are the advantages and disadvantages of dovetail joints?

The interlocking dovetail joint has a large gluing area, further adding to its strength. Hand cut dovetail joints require precise handsaw and chisel skills, and can be fiddly to mark out and cut. If dovetail joints are poorly made they will lose the advantage of strength and durability.

What are the pros and cons of dovetail joints?

The interlocking dovetail joint has a large gluing area, further adding to its strength. Hand cut dovetail joints require precise handsaw and chisel skills, and can be fiddly to mark out and cut. If dovetail joints are poorly made they will lose the advantage of strength and durability.

Are dovetail joints difficult?

Hand-cutting a dovetail joint is kind of a woodworking high-wire act; one slip of the saw or chisel and the joint either won’t fit together or will look sloppy. It takes a lot of time to master the ability to cut dovetails quickly and well (by hand or machine), without a lot of fussing around.

When did they stop using dovetail?

According to oldcopper.org, coppersmiths kept on dovetailing the seams until about 1900, after which better joinery technology made the time-consuming dovetail process obsolete. This means that a dovetailed pot or pan could have been hand-cut or machine-cut.

Do you need to clamp dovetails?

I bang them together with a rubber mallet. I always make sure the side beieing assembled is down on the surface of the table to avoid splitting. In other words I’m hammering the pin board into the tail board not hammering the tail board onto the pin board. No need for clamps if you dovetails are tight.

Is dovetail the highest quality?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

What is the best joint for joining timber end to end?

Finger joints provide face- or edge-grain gluing surfaces to end-to-end joints for a stronger glue bond. Any joint that butts end grain to end grain will be weak because you’re gluing wood fibers at their porous ends instead of along their sides.

What is the easiest joint for woodworking?

Butt joints are the easiest joint to make and have been used for centuries. You need to account for the width of the corners that over lap when making size cuts with this joint but it isn’t that hard. Screws, glue, nails all can be used to attach the joint, depending on the use the box will be used for.

What joint is used in fine woodworking only?

Dovetails are usually viewed as the ultimate fine woodworking joint for this use. However, I want explore some other joints that work just as well, and that Shaper is well suited to make.

Are dovetail joints difficult?

Hand-cutting a dovetail joint is kind of a woodworking high-wire act; one slip of the saw or chisel and the joint either won’t fit together or will look sloppy. It takes a lot of time to master the ability to cut dovetails quickly and well (by hand or machine), without a lot of fussing around.