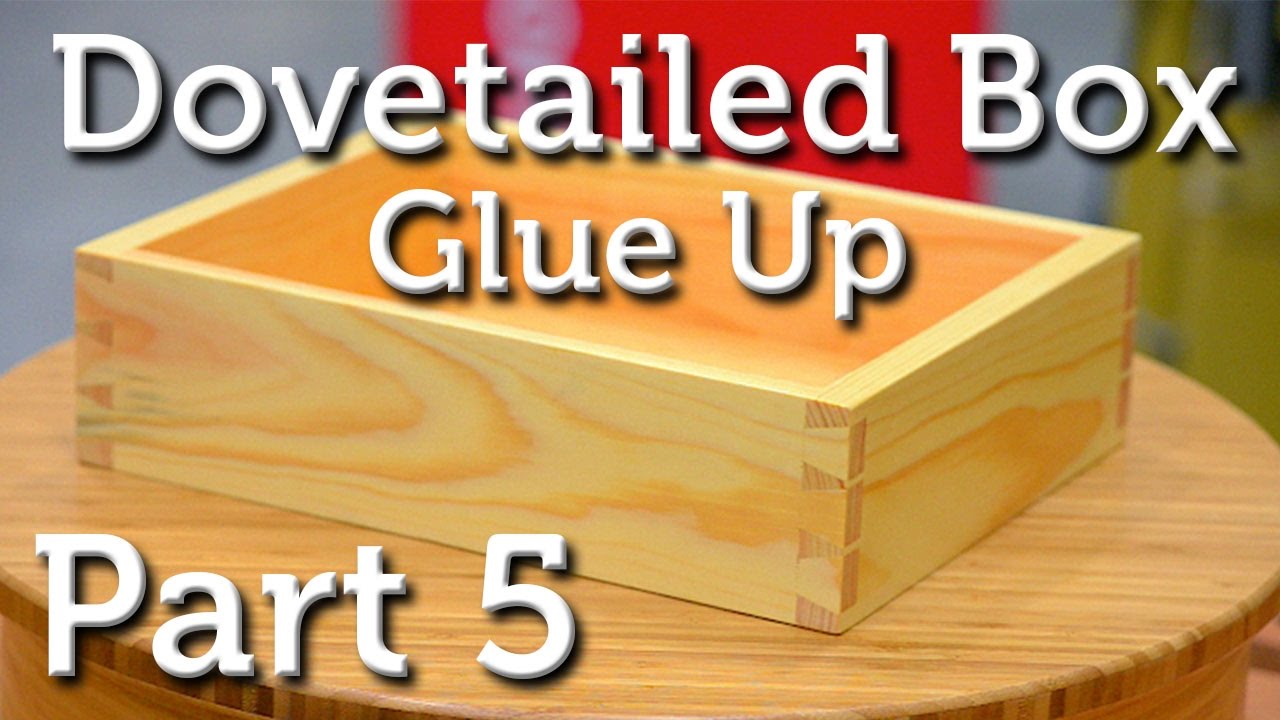

Being a mechanical joint, a dovetail does not rely on glue for strength in drawer box construction. The glue is only needed to keep the joint from sliding apart sideways. To avoid hydraulic problems, I just apply a thin coat of glue to the diagonals of the joint and leave the rest of the joint dry.

Does a dovetail joint require glue?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

Do you need to clamp dovetails?

I bang them together with a rubber mallet. I always make sure the side beieing assembled is down on the surface of the table to avoid splitting. In other words I’m hammering the pin board into the tail board not hammering the tail board onto the pin board. No need for clamps if you dovetails are tight.

What are the disadvantages of a dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

What makes a dovetail joint strong?

Methods. The dovetail joint is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

What type of glue should be used with a dovetail joint?

Titebond III is what I use. It has superior water resistance to Titebond II. Either one works well if the gaps are small and the adhesive is stronger than the wood. If the gaps are on the loose side, epoxy resin is a better choice.

What glue to use on dovetails?

In years of both hand cutting and machine cutting dovetails, I have never had a problem with PVA glue unless I was using an odd species of oily wood. Early on when I cut dovetails too tightly, most of the glue would be squeezed out when assembling the joint.

What are the rules for dovetail?

RULES: Dovetail is a better ball stroke play game played with a partner, with each player having their gross score recorded on a minimum of 8 holes. Both partners play the holes individually to the stroke play format and then select which score is entered on the card.

How deep should a dovetail joint be?

Two-step Shouldered Joints With a 3⁄4″-diameter flush-trimming bit in your router, plow out the dado to 3⁄16″ deep. Next, take your router with a tem- plate guide and dovetail bit, set it to 9⁄16″ deep (without moving the straightedge) and make the cut into the case side.

How tight should dovetails be?

If you can use your fist as a hammer to nudge them together, they’re just right. By the way, when you realize they will fit nice and snug, (hopefully by the time they are less than half way down) take them apart and don’t put them together again until you glue them.

Is a finger joint stronger than a dovetail joint?

For box joint, some people put a lot more fingers than it is possible to do with Dovetail. In this case, the gluing surface is larger, and the joint is likely stronger. Also, some find a way to hide a finish nail in the joint. Dovetail has the advantage of a mechanical lock independent of the glue.

Are dovetails the strongest of all joints?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

What is the strongest joint in woodworking?

Mortise and tenon joints have stood the test of time for their remarkable strength. This traditional joint involves a projecting piece of wood, called a tenon, securely fitting into a corresponding cavity, a mortise. It can be reinforced with glue or wedges for stability for a stronger hold.

What is the best angle for a dovetail joint?

Although softwoods are more compressible than hardwoods, you needn’t change the dovetail angle to add strength to the joint. Any angle between 7° and 15° will work, regardless of the wood. But stay within that range. If you go below 7°, you’ll start to lose the mechanical strength of the dovetail.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

What is the best angle for a dovetail?

Do you need glue for wood joints?

The best joins support themselves. Mortise and tenon and dovetail joints are examples. These simply need glue to prevent them from slipping out of position rather than to add any great strength. The wedged mortise and tenon below is an excellent example.

What are the basics of a dovetail joint?

The dovetail joint is made up of two parts. The tails are the flared, triangular shapes, cut through the thickness of one board. The pins are the more slender projections, cut along the grain of the other board. There is an ongoing argument/discussion as to which part should be cut first.

What is the process of a dovetail joint?

there are two parts to a dovetail joint—a pin side and a tail side. The tails look like the tail of a dove (hence the name), and the pins are straight cuts. The two differently shaped sides fit together to form an interlocking trapezoid. The joint will now resist being pulled apart in least one direction.

Do dowel joints need glue?

Dowel joints are an absolute joy to glue up, because the joint’s design only allows it to move in one direction – together. Unlike biscuits, dowels won’t allow the mating parts to move vertically or laterally during the glue-up.

What glue do carpenters use?

Polyvinyl acetate (PVA) glue is the most common type of wood glue. This type includes typical white and yellow glues, or what are commonly called “carpenter’s glue.” Iit can be used for many – but not all – projects.

How can I improve my dovetails?

Yes, the three things I did that truly improved my dovetails are cutting a clean, deep shoulder line on both the tail and pin boards, getting serious about transferring the tails to the pin board accurately, and understanding how those layout lines inform paring when fitting the pins to the tails.

Can you put dovetails in plywood?

A wide variety of methods can be used to make dovetail plywood drawer boxes. They are generally considered by the woodworking industry as time-consuming and difficult to make. The dovetails can be cut by hand with a dovetailing saw and chisel or you can use a dovetail jig and router.

How thick should dovetails be?

That said, 3/8” gives me room for a drawer bottom groove and enough meat on the drawer sides to compensate for wear and support to the drawer bottom. I then work out how many tails I want. Usually I like tails to be between 1” and 1 ¼” on projects reliant on dovetails more for strength than aesthetics.

Are dovetail joints difficult?

Hand-cutting a dovetail joint is kind of a woodworking high-wire act; one slip of the saw or chisel and the joint either won’t fit together or will look sloppy. It takes a lot of time to master the ability to cut dovetails quickly and well (by hand or machine), without a lot of fussing around.

How do you mark a dovetail joint?

Mark out the two ‘half-pins’ at the edges on the first piece of wood. The ‘pins’ are the bits of wood between the tails so there are two half-pins; one each side. The general rule is that they measure half the thickness of timber plus around a mm, so the two dots on the shoulder line are 7mm in from each edge.