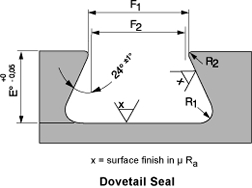

As a rule of thumb the dovetail’s maximum width should occupy approximately 1/ 2 to 3/ 4 of the gasket’s width (leaving a 1/ 4 – 1/ 8 of gasket width on each side). For larger gasket widths, multiple dovetails can be made side-by- side, facing the same direction or inverted.What are the standards for dovetail design? Mike Walker 01/06/2024 As a rule of thumb the dovetail’s maximum width should occupy approximately 1/ 2 to 3/ 4 of the gasket’s width (leaving a 1/ 4 – 1/ 8 of gasket width on each side). For larger gasket widths, multiple dovetails can be made side-by- side, facing the same direction or inverted.

What is the standard angle for a dovetail?

Lower (7° to 9°) angles are often advised for joining hardwoods, while higher angles (10° to 14°) are recommended for softwoods and even higher angles (14° to 18°) for half-blind dovetails.

What size are standard dovetails?

Dovetails come in several different types and sizes depending on manufacturer, but the most common are the 11 mm and 3⁄8 inch (9.5 mm). Some other less known, but currently commercially available dovetail mounts, are 12, 13, 13.5, 14, 14.5, 16, 16.5, 17 and 19 mm.

What are the proportions of a dovetail?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What is the important information about the dovetail joint?

Dovetail joints are known for their inherent strength and resistance to being pulled apart (tensile strength). A dovetail joint has a series of pins and tails in a trapezoidal shape and once glued a dovetail joint has no need for mechanical fasteners.

What is the strongest angle for a dovetail?

Any angle between 7° and 15° will work, regardless of the wood. But stay within that range. If you go below 7°, you’ll start to lose the mechanical strength of the dovetail. Go above 15°, and you’ll leave too much short grain at the tips of the tails, which weakens the joinery.

What are the rules for dovetail joints?

The shoulder line should be fractionally bigger (0.5mm) than the thickness of the wood to allow for a little overhang when the joint goes together. Mark out the two ‘half-pins’ at the edges on the first piece of wood. The ‘pins’ are the bits of wood between the tails so there are two half-pins; one each side.

Are 3 8 and 11mm dovetail the same?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

What is the most common dovetail ratio?

With regard to what to use, a common recommendation is 1:8 for hardwoods and 1:6 for softwoods. These recommendations are based on some arguments related to strength. However, people use a lot of different ratios depending on application and aesthetics.

What is the minimum thickness for a dovetail?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

How do you dimension a dovetail?

Dovetail slides that must be machined accurately to a given width are commonly gaged by using a gage pin of known diameter and measured as indicated by the dimensions x and y. The gage pin should be small enough so that the point of contact e is somewhat below the corner or edge of the dovetail.

What is angle 1 to 8 dovetail?

A 1:8 ratio – one unit horizontal with eight matching units drawn vertical – is an angle of 7.1 degrees.

What ratio is a 14 degree dovetail?

There is no hard and fast rule when it comes to dovetail angles. Commonly accepted ratios are 1:8 for hardwoods and 1:6 for softer timber. This 14° marker equates to a ratio of 1:4.

What is the most popular dovetail joint?

Single-lap Dovetail The single-lap (known to many folks as a half-blind dovetail) is the best known of the dovetails since it’s used to join the front to the sides of a drawer.

What is an English dovetail joint?

A dovetail joint is a locking joint. The English dovetail construction tends to allow for the largest possible drawer storage capacity. French dovetail construction is used for more elaborate features such a curved, bowed design.

What is the weakness of dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

Are all dovetail bits 14 degrees?

You’ll need a jig to make most dovetail joints, as well as a guide Bushing for your router. Check the instructions with your Dovetail jig to select a bit with the appropriate angle, which will usually be somewhere between 7 and 14 degrees.

What ratio is a 14 degree dovetail?

There is no hard and fast rule when it comes to dovetail angles. Commonly accepted ratios are 1:8 for hardwoods and 1:6 for softer timber. This 14° marker equates to a ratio of 1:4.

What is angle 1 to 8 dovetail?

A 1:8 ratio – one unit horizontal with eight matching units drawn vertical – is an angle of 7.1 degrees.

Is 11mm dovetail the same as 3 8?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

Is dovetail the highest quality?

Dovetail drawers are considered a sign of quality, a hallmark of solid construction, and are generally recommended for anyone in the market for cabinets.

Should dovetail joints be glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

What makes a dovetail joint so strong?

The dovetail joint is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

How hard is it to make a dovetail joint?

Of the four types of dovetail joints (through dovetail, half blind dovetail, secret mitered dovetail, and the sliding dovetail), the through dovetail is the most basic method, and a perfect one for hand cutting. Contrary to what seems to be popular belief on the internet, they are not really all that hard.

What is the standard 11mm dovetail?

The standard 22 tip-off dovetail in the US is 3/8″ at the bottom and up to 1/2″ at the top. The European 11mm dovetail is typically 11mm at the top and perhaps 8mm at the bottom. The 11mm dovetail typically has a 60 degree angle from the bottom inside corner to the top where the 3/8″ is typically 45 degrees.