Though it isn’t a very good choice for plywood either, glued finger joints should offer better strength. Dovetails provide very little long grain to long grain gluing surfaces in plywood. There are other things to consider with plywood also such as the number of plies & voids.

What are the limitations of a dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

What wood is best for dovetails?

There are a lot of different types of wood out there but almost all woodworkers around the internet agree that the best wood to practice dovetails on is poplar. From my own experiences, I would have to agree. It has some of the best properties from both softwood and hardwood while not having big open grain.

Where can a dovetail joint be used?

A dovetail joint or simply dovetail is a joinery technique most commonly used in woodworking joinery (carpentry), including furniture, cabinets, log buildings, and traditional timber framing.

What are the rules for dovetail joints?

The ‘pins’ are the bits of wood between the tails so there are two half-pins; one each side. The general rule is that they measure half the thickness of timber plus around a mm, so the two dots on the shoulder line are 7mm in from each edge.

Should dovetail joints be glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

Is a finger joint stronger than a dovetail joint?

For box joint, some people put a lot more fingers than it is possible to do with Dovetail. In this case, the gluing surface is larger, and the joint is likely stronger. Also, some find a way to hide a finish nail in the joint. Dovetail has the advantage of a mechanical lock independent of the glue.

Are dovetail joints worth it?

Making sure that you pick a drawer joint that can withstand this type of wear and tear is crucial to the longevity of your kitchen cabinets. Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

How tight should a dovetail joint be?

If you can use your fist as a hammer to nudge them together, they’re just right. By the way, when you realize they will fit nice and snug, (hopefully by the time they are less than half way down) take them apart and don’t put them together again until you glue them.

What is the best angle for a dovetail?

Percy Blandford, who has been writing about woodworking for a long time, writes in “The Woodworker’s Bible” that any angle between 7.5° and 10° is acceptable. The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint. Glue may be applied to the mating surfaces.

What is the strongest joint in woodworking?

Mortise and tenon joints are widely regarded as one of the strongest and most reliable woodworking joints. They involve creating a mortise, or a hole, in one piece of wood and a tenon on the end of the other piece, which fits into the mortise.

When did they stop using dovetail joints?

So manufacturers moved away from dovetails. Hand-cut dovetailing was the default until 1860 when uniform machine-cut joints were introduced. But fine cabinetmakers persisted in fitting their joints by hand until the early 1900s, and cabinetmakers in Europe cut dovetails by hand well into the 1930s.

Is a dovetail joint strong or weak?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint.

What is the minimum thickness for a dovetail?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

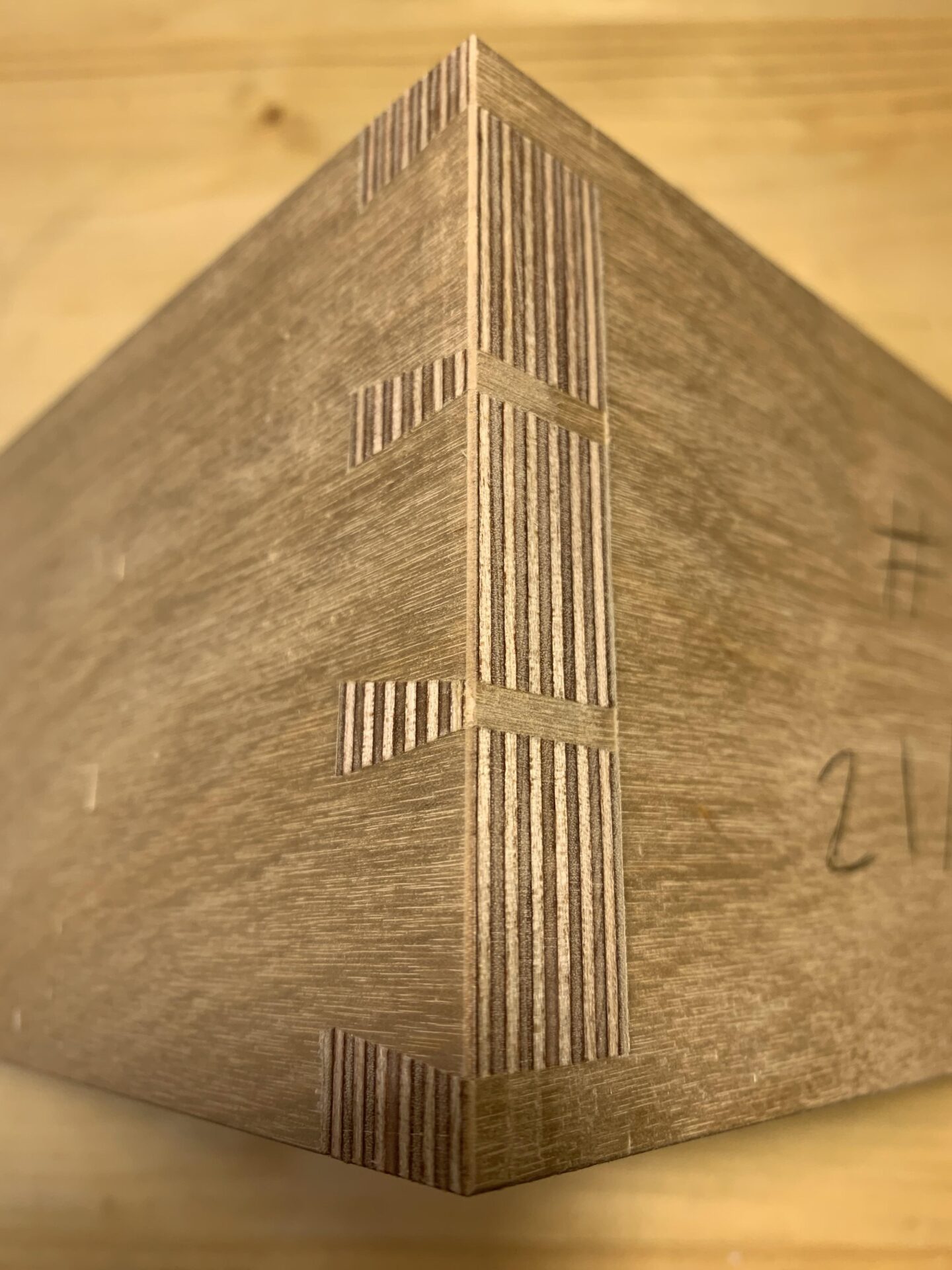

What are the strengths and weaknesses of a dovetail joint?

The interlocking dovetail joint has a large gluing area, further adding to its strength. Hand cut dovetail joints require precise handsaw and chisel skills, and can be fiddly to mark out and cut. If dovetail joints are poorly made they will lose the advantage of strength and durability.

Is a dovetail joint strong or weak?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint.

Are dovetail joints strong?

Dovetail joints are very strong by design and they also offer an attractive finish that is a true sign of craftsmanship. Professionally cut and glued dovetail joints are virtually impossible to separate.

Are dovetail joints permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint. Glue may be applied to the mating surfaces.

How difficult is a dovetail joint?

Hand-cutting a dovetail joint is kind of a woodworking high-wire act; one slip of the saw or chisel and the joint either won’t fit together or will look sloppy. It takes a lot of time to master the ability to cut dovetails quickly and well (by hand or machine), without a lot of fussing around.

How hard is it to make a dovetail joint?

Of the four types of dovetail joints (through dovetail, half blind dovetail, secret mitered dovetail, and the sliding dovetail), the through dovetail is the most basic method, and a perfect one for hand cutting. Contrary to what seems to be popular belief on the internet, they are not really all that hard.

What is the weakest joint in carpentry?

A butt joint uses a simple technique whereby two pieces of material are joined together at their ends, without any special shaping or cutting. Although it is simple, the butt joint is also the weakest of the wood joinery types.

How much weight can a dovetail hold?

Standard 9′ cleated dovetail (with wood between the runners) features a lifting capacity of approximately 8,000 lbs and carrying capacity of 4,000 lbs.

How big should a dovetail joint be?

What is an impossible dovetail joint?

Press a dovetailed board into another board with matching sockets, and you’ve created woodworking’s most iconic joint. The dovetails and sockets wedge the boards together, so the joint can’t pull apart; the only way to disassemble it is to lift the dovetailed board back out of the sockets.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.