We all know that sanding, grinding, and polishing surfaces are essential for a variety of reasons. But it can be hard to find the right type of belt for your needs. There are so many different types available, from abrasive belts to sanding belts, and each one has its benefits and drawbacks.

The Best Abrasive Grain Type For Knife Making

When it comes to sharpening knives, belts are often the most efficient option. This is because they can handle the small angles of a knife blade without needing to be changed out as you would with an abrasive stone. As well, their compact size makes them easy to control and maneuver around the blade’s edge without posing a safety risk. For these reasons, it’s helpful to have a high-grit belt on hand.

The best abrasive type for knife making is aluminum oxide because it cuts faster than the other options available. It won’t fill up with metal filings or dull as quickly either. Aluminum oxide belts are used in all types of knife grinding applications, from sharpening blades to removing excess metal from an edge.

Why Ceramic Belts Are The Best Belts For Knife Making

There are a couple of reasons why ceramic belts would be the best belt for knife making. They cut very quickly, but they don’t leave much heat or debris when cutting the metal. This is essential for sharpening and grinding knives because you want to make sure you can work with precision and not cause damage to the blade in the process.

Secondly, ceramic belts are perfect for finishing off a knife or making it more precise because they don’t leave behind any debris when they cut the metal. Dirt and dust can create problems when trying to achieve a fine edge on a blade, so it’s best to have a belt that minimizes this risk. This is less of an issue with more coarse belts, but it is still good to know.

Alternative Abrasive Grains For

If you don’t have enough money for a ceramic belt, diamond is the only alternative option worth considering. However, it’s important to note that many people do not use diamond belts when sharpening knives because they are so expensive. They are also quite risky to work with because their brittleness can cause them to shatter and fly apart when you try to cut through metal.

Ceramic belts, on the other hand, are much safer and not as expensive. And because they can run pretty quickly, even in coarse grits such as 100 or 120, they won’t be worn out too fast either. Ceramics is a good material for sharpening knives because it doesn’t heat up as quickly as a diamond belt.

There’s a lot to be said for the best ceramic grinding belts, and they really should form the basis of your sharpening setup because they are affordable, fast-cutting, and safe to use.

What About Grit Size?

Grit size refers to the number of abrasive particles per square inch of the belt. This affects how quickly it cuts through metal on your knife, and grits range from as high as 600 down to 100. You’ll need a fine or extra-fine grade for finishing off sharpening tasks.

For coarse belts, you’ll need to be careful when using them for finishing. It’s easy to go too slowly, which might cause the belt to fracture and shatter, so it’s best to start with a coarse belt before switching over to your fine one.

Selecting The Best Belt Backing For Your Application

Backing refers to the type of material that makes up the belt backing, and it’s crucial because its characteristics can affect how much flexibility a belt has.

The best backing for grinding belts is leather or cloth because they provide strength and agility. Leather is often preferred, but material comes into play if you’re trying to achieve more precise tasks.

When you want to purchase new grinding belts, it can be overwhelming to try and figure out which are the best ones on the market today. There are many different types with unique functions that make them ideal for a variety of applications. It’s essential to understand this before making any purchases because it will help narrow down your options over time.

Flexible Vs Heavy Backings

When you’re trying to select the best belt for your application, consider two standard backings. The first is called flexible backing, and it’s used for light applications such as finishing tasks requiring a lot of precision.

The second backing is called heavy backing, and it’s used for heavy-duty grinding jobs. It would be ideal for getting rid of rust, paint, or other rigid materials because they can run much more quickly.

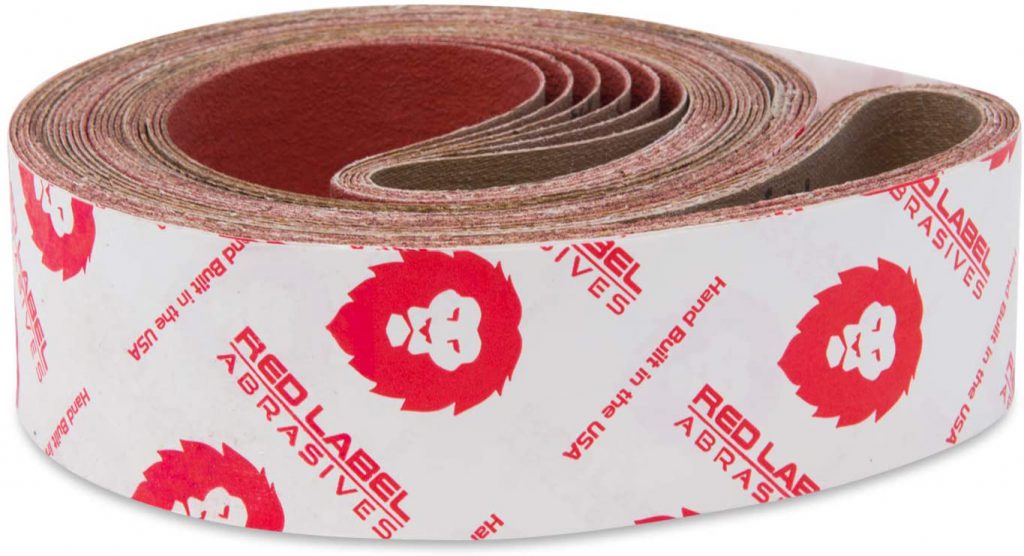

Knife Making Belts From Red Label Abrasives

Red Label Abrasives is the top brand when it comes to grinding belts. They offer an extensive range of different types, so you’ll be able to find the best belt for whatever task you have in mind.

Now that you know what to look for, here are the 8 best belts on the market right now. We’ve listed them in order of ascending price so you can start at the cheapest and work your way up to more expensive options if need be!

Zirconium Oxide (Zirconia) Sanding Belts

The first of the best grinding belts on our list are made from zirconium oxide (zirconia), and they’re also called zirconia sanding belts. They work great for finishing tasks like sharpening knives and often come with Type 27 backings. If you want to buy these separately, then Type 23 is a good option.

These zirconia sanding belts are trendy because they can sprint and don’t require lubrication during use. Many people like to put them in the #120 – #180 grit range, and these offer a nice balance between speed and quality.

If you want something that will sharpen your knives as well as remove rust, paint, or corrosion from your metal surfaces, then zirconia sanding belts are a good choice because they’ll offer you a high level of precision.

Ceramic Sanding Belts

Next on our list are ceramic sanding belts, also known as vitrified aluminum oxide sanding belts. This is because they’re made from harsh particles that are layered on the belt backing. They’re great for achieving a high level of precision when you’re working with unique materials like plastics and melamine surfaces.

These sanding belts are most popular with professionals who use them for finishing tasks. They’re usually the best choice if you want to sharpen a knife or remove rust from your metal surfaces because they can do a fine job.

Ceramic sanding belts work quickly and don’t require lubrication. Since they’re designed to remove paint, corrosion, and other rigid materials, it’s best to put them in the #80 – #120 grit range.

The Five Common Types of Belt Sanding Machines

There are five common types of belt sanding machines that people use to achieve different results. Since each device has its unique purpose, it’s essential to understand their differences before making any purchases.

Hand Powered Belt Sander

The first type that you’ll come across is the hand-powered belt sander. It’s also known as a manual belt grinder because it requires human power to operate. People typically use them to do things like sharpening knives, so if you want to achieve an extra fine edge on your blade, this might be the best choice for you.

Tube Belt Sanders

The second type is the tube belt sander. As the name suggests, it’s shaped like a tube, and you use it by moving it up and down in your hand. It’s commonly used for sharpening plane irons, so if that sounds like something you need to do, then this might be worth looking at.

Belt File Sanders

Next up on our list is the belt file sander. You’ll use it by moving it back and forth on a surface so that you can achieve high levels of precision when sharpening your knife. It’s known as an ‘old school’ option, but it’s still pretty popular with people who want to fix damaged blades.

Floor Belt Sanders

Floor belt sanders are the fourth type of machine you’ll come across, and they’re also known as floor-standing belt grinders. They do what their name suggests by helping you remove paint, rust, or corrosion from large surfaces like floors, so it’s best to buy them if you have a lot of floors in your home to work on.

Stationary Belt Grinders

Finally, we have the stationary belt grinder. These are heavy-duty machines that you put on a workbench and use by moving your hand back and forth. They’re similar to floor-standing belt grinders because they do jobs like removing rust from metal surfaces, but they usually take up a lot of room, so you need reasonably ample space to work with them.

These are all of the different types of belt sanding machines that you’ll come across, so now it’s time to look at how they can benefit you. Let’s get started!

The Four Main Abrasive Grains

The four main abrasive grains are aluminum oxide, garnet, silicon carbide, and zirconia. Each one has the potential to do the job well depending on what you’re working with, so you must know how they work before making any purchases.

Aluminum Oxide Sanding Belts

Aluminum oxide sanding belts are made from aluminum oxide grains. They’re the most popular abrasive grain globally, and they can be found in products like grinding discs, belt sanders, and even some drill bits.

They work exceptionally well for sharpening blades or removing rust because they can easily cut through hard materials. They’re usually the best choice if you have any tough jobs outdoors like cutting down trees or sawing logs.

Zirconia Alumina Sanding Belts

Zirconia Alumina sanding belts are made from zirconium oxide and aluminum oxide. They’re one of the most common abrasives globally, and they’re also often used with garnet or silicon carbide.

They can be found in products like belt grinders, knife sharpening stones, and some types of sandpaper. They’re usually used for jobs like removing rust, paint, or wood because they produce fewer sparks than aluminum oxide belts when you cut them with a blade.

Ceramic Grit Sanding Belts

Ceramic grit sanding belts are made from zirconium oxide and aluminum oxide. They’re very similar to zirconia alumina abrasives, but they have a lower thermal conductivity.

They can be found in products like belt grinders, knife sharpening stones, and some types of sandpaper. They tend to leave a more refined finish than aluminum oxide belts, so they’re a popular choice if you have any intricate jobs to do.

Silicon Carbide Sanding Belts

Silicon carbide sanding belts are made from silicon carbide grains. They’re the second most abundant mineral in the world, so that they can be found in a ton of products like grinding wheels, belt grinders, drill bits, and even some knife sharpening stones.

They work by flaking off pieces of themselves as you cut, which is a very efficient way to remove rigid materials. They’re usually the best choice if you have any jobs to do involving metal because they can cut through it without too much difficulty.

Choosing the Right Sanding Belt Grit

Now that you know a bit more about the different abrasive grains, it’s time to talk about how to choose the correct sanding belt grit. You should keep in mind a few things for this because not all products are created equal!

The first thing you need to think about is what material you’re going to be using the belt on. It’s always best to start with a coarse grit if you’re trying to cut through rigid material because that will give you the most efficient results in one or two rounds instead of going through several fine grits before you get the same results.

The next thing that you need to consider is how precise your cuts need to be. If you’ve got any intricate jobs to do like cutting grooves in wood or engraving metal, you should go with a fine-grit sanding belt because they can clean up the surface better than coarse grits.

Finally, your belts must be wide enough for the machine that you’re using them with.

Our Top Picks

Red Label Grinding Sanding Belts

Grind as you mean it! Stop wasting time with cheaper sanding products that wear down immediately. Red Label Grinding Sanding Belts are premium, top-of-the-line ceramic material, specifically designed to last through the most intense grinding jobs. They are rated for heavy welding removal and deburring too!

These sanding belts are specially designed for sanding and grinding metal surfaces. These sanding belts are the perfect medium for welding metal.

Red Label Grinding Belts are made of ceramic grain, earning them the title of “the toughest material in the abrasive industry.” Red Label is long-lasting compared to Zirconia belts because it doesn’t blunt as quickly. It will provide a continuous sharp cut for its entire life span without losing efficiency or power – ask professional detailers all over town that use these exclusively.

No matter what you’re sanding, you need to use Red Label Sandpaper if you want the best finish. Why? Company construct ultra-strong and precision-built belts with high-quality bi-directional tape joints – so no more blistering or bowing. The durable backing means our grit doesn’t fall off like others on the market. Best of all, you can run these belts wet or dry! Perfect for any woodworker building furniture at home who is concerned about dust particles damaging the finer nuances in their work.

Top benefits of Red Label Grinding Sanding Belts

The best sanding belts are the most challenging material in the abrasive industry. Ceramic grain is long-lasting compared to Zirconia because it doesn’t blunt as quickly. It will provide a continuous sharp cut for its entire life span without losing efficiency or power. You can also run these belts wet or dry, which is perfect for any woodworker building furniture at home concerned about dust particles damaging the finer nuances in their work.

Pros

- Long-lasting

- Tough material

- Good value

Cons

- May was not ideal for super fine finish work because the grains are large

- Take time to wear in before abrasive quality is achieved

Final Words

If you want the best finish and strongest grind, Red Label Grinding Sanding Belts are your go-to. These belts will not blister or bow like other brands on the market because of their durable backing and high-quality tape joints. The unique properties of ceramic grain allow it to provide a continuous sharp cut through its entire life span without losing efficiency or power and leave a lovely finish on metals when used on a flat platen!

XTYML Aluminum Oxide Sanding Belts

Aluminum oxide sanding belts are one of those things that you see in every DIY store, but very few people use them.

The XTYML sanding belts are an excellent alternative to using paper or foam sandpaper, especially if you’re looking for a more reliable product.

Sandpaper is designed to remove surface material by scratching, but aluminum oxide is or polish, which leaves a smoother finish. They’re made of high-grade alumina particles, which are highly durable and can withstand extreme temperatures.

Alumina is also more durable than sandpaper, and it doesn’t scratch easily either. So these aluminum oxide sanding belts can last for many years on your surface. Each strap comes with 15 pieces of 80, 120, 150, 240, and 400 grit sandpaper.

If you need to strip a surface or remove a layer of rust, aluminum oxide sanding belts are a much better choice.

The best thing about aluminum oxide sanding belts is that you can use them in any direction, making them suitable for use with both handheld and powered tools.

They’re also ideal for removing rust from metal surfaces and smoothing out wood or plastic moldings. They’re also suitable for polishing plastic and leather upholstery. The sanding belts are highly flexible and can withstand the forces of extreme temperatures and humidity. They’re also easy to clean and maintain.

Aluminum oxide is also non-conductive, so that you won’t have any problems with static buildup or static cling. So you won’t have to worry about using the belt on anything flammable or conductive.

You can use the aluminum oxide sanding belt on wood, metal, plastic, and other materials.

So if you’re looking for a reliable aluminum oxide sanding belt that will provide you with long service life and superior performance, then these are a great choice.

Top benefits of XTYML Aluminum Oxide Sanding Belts

The abrasive belt size is 10.16 x 60.96 cm, 3pcs x 80 grit, 3pcs x 120 grit, 3pcs x 150 grit. Three pcs of 240 and 400 each to meet your requirements for different materials and applications. The best thing about the XTYML Sanding Belts is that they can be used in any direction, making them suitable for use with both handheld tools and powered tools.

They are durable because the 4×24 sand belts are made of high-quality alumina particles with good abrasion resistance antistatic and anti-clogging functions, making them high-quality. They are also easy to use and can be maintained after use, making them an excellent sharpening stone for drills, saw blades, knives, and other tools. Aluminum oxide sanding belts provide heavy-duty stripping and polishing tools for wood, aluminum, fiberglass, rubber plastic, and non-ferrous metals, offering you maximum performance.

Pros

- The sanding belts are highly flexible and can withstand the forces of extreme temperatures and humidity

- They’re also easy to clean and maintain

Cons

- Grit is not coarse enough

- Too many high grits in a package

Final Words

If you’re looking for a reliable aluminum oxide sanding belt that will provide you with long service life and superior performance, then these are the best choice. The abrasive belts can be used in any direction, making them suitable for handheld and powered tools.

They are durable because the 4×24 sand belts are made of high-quality alumina particles with good abrasion resistance antistatic and anti-clogging functions, making them high-quality. They are also easy to use and can be maintained after use, making them an excellent sharpening stone for drills, saw blades, knives, or other tools. Aluminum oxide is nonconductive, so you won’t have to worry about static buildup or static cling and can be used on wood, metal, plastic, and other materials.

Knife Makers Sanding Belts

These sanding belts are made for all kinds of knife makers. The different grits make it possible to work quickly on rougher surfaces while maintaining precision for finer details. With these belts, knife making can become even more fun and less frustrating!

Tearing your knives by accident has never been this easy with these wet or dry woodworking tools that will surely get you what you need in no time at all. If you want something heavy-duty, then try one of these 6-pack sets that include every hand tool imaginable to keep your blades beautiful and structurally sound.

Top benefits of Knife Makers Sanding Belts

Knife Makers Sanding Belts are explicitly designed for knife makers and come in a variety of grits.

The P36 is ideal for grinding and hogging blades, while the P120 can be used to shape your knives. Wet or dry applications mean that these belts can work with water and oil-based products like honing compounds and mineral oils. Precision engineered bi-directional tape joint means you won’t have any clogs when sanding, plus it’s easy to change out the belt if need be! The resins over resin bonding also ensure long life because there are no contact points between layers of cloth backing for corrosion to set in. Give Knife Makers Sanding Belts a try today!

Pros

- The best way to sharpen your knives

- Get the perfect edge every time

Cons

- Sanding belts do not work well with all blades

Final Words

As a knifemaker, you must have the proper tools to get your knives in shape. The Knife Makers Sanding Belts are specifically designed for this task and come with different grits from coarse up to finishing. Wet or dry applications make these belts versatile enough for any situation, while precision-engineered bi-directional tape joint ensures no clogs when sanding. Resins over resin bonding also provide long life because there are no contact points between layers of cloth backing for corrosion to set in!

Norton Blaze Sharpening Belts

Norton Blaze belts are the best choice for mild steel, stainless steel, cobalt, chrome, Inconel, and Titanium applications. We recommend these belts for changing grits to get that perfect edge.

These premium grinding belts only use Norton SG ceramic abrasive grain, which cools down after cutting and lasts 50% to 200% longer on every steel blade metal than aluminum oxide belts. This means perfect edges on your blades for a long time to come!

With the Norton Blaze Sharpening Belts, you’ll get a grit stock removal that is 20% faster than competitors. This product lets users have the most vital metal integrity with an optimum lubricant for longer belt life. Get more productivity and the lowest total grinding costs with these quality belts!

The Norton Blaze Sharpening Belts offer durability and cutting-edge technology that keeps your sharpener running at peak performance. The waterproof backing keeps it from transferring to knives. The double-sided design allows professionals to grind in any direction for more efficient sharpening. The advanced resin bond system offers even greater belt life than before. It also includes super-sized grinding lubricant for more excellent blades during their lifespan, plus professional-grade grits suitable for various tasks.

Norton Blaze is the perfect tool for your knife or blade. It will turn your everyday kitchen cutlery into a work of art by giving you professional results with every use. The grit on this belt has an aluminum oxide, letting it bond well to surfaces like stainless steel and other metal by optimizing material integrity with each pass. Thanks to Norton Blaze belts, give all your knives, blades, scissors, and saws the quality finishing touches they deserve!

Top benefits of Norton Blaze Sharpening Belts

Norton Blaze Sharpening Belts offer durability and cutting-edge technology that keeps your sharpener running at peak performance. The waterproof backing keeps it from transferring to knives. The double-sided design allows professionals to grind in any direction for more efficient sharpening.

Pros

- Low Tension

- Super-sized Lubricant

- Professional Grade Grits Suitable for Various Tasks

Cons

- Some belts don’t cut down the center of the blade

Final Words

Ceramic sharpening belts are an excellent choice for your knife or blade. They will turn your everyday kitchen cutlery into works of art by giving you professional results with every use. The grit on this belt has an aluminum oxide, letting it bond well to surfaces like stainless steel and other metal. When used correctly, these ceramic sharpening belts can help retain the grain of the material while also maximizing its integrity with each pass while providing minimal edge fraying! If you’re considering buying one, I would recommend Norton Blaze Ceramics Sharpener Belts as they offer durability and cutting-edge technology that keeps your sharpener running at peak performance. The waterproof backing keeps it from transferring to knives. The double-sided design allows professionals to grind in any direction for more efficient sharpening. It also includes super-sized grinding lubricant for more excellent blades during their lifespan, plus professional-grade grits suitable for various tasks! So what are you waiting for? Get yours now!

Tonmp Metal Grinding Sanding Belts

Tonmp’s line of grinding sanding belts is perfect for steel, stainless steel, cast iron, carbon steel. The ceramic grain provides the most extended life available for this abrasive, and the topcoat reduces heat buildup. Perfect for heavy-duty projects where metallurgy is essential!

Tonmp’s ceramics are used in many industrial applications. They last longer than zirconia by miles-perfect when you need to grind metal that resists wear quickly or want cool without interference from harsh blades. Our 120 grit belt is excellent on stainless steel and other hard materials! And our low profile makes it easy to use even in tight spaces like between gears! Enjoy the reliable performance with Top products.

Top benefits of Tonmp Metal Grinding Sanding Belts

Tonmp’s Grinding Belts is the perfect abrasive for steel, stainless steel, cast iron, and carbon steel. Trump’s ceramics last longer than zirconia by miles-perfect when you need to grind metal that resists wear quickly or want cool without interference from harsh blades. Our 120 grit belt is excellent on stainless steel and other hard materials! And our low profile makes it easy to use even in tight spaces like between gears! You can’t go wrong with Top products.

Pros

- Prolongs the life of your grinding wheel

- Lessens heat buildup

- Sharp, clean cuts

Cons

- Lack of coarse grit

- Belt is usually too long and can be hard to manage

- Belt does not last as long as other belts on the market

Final Words

Tonmp’s has a few unique features that set them apart from other competitors when it comes to metal grinding and sanding belts. The ceramic grain provides the most extended life available for this abrasive. At the same time, their topcoat reduces heat buildup-perfect when you need to grind metal quickly or want to cool without interference from harsh blades.

Sackorange Metal Grinding Sanding Belt

Metal Grinding Belts are not just for woodworking shops. The Sackorange Sanding Belt is a premium industrial grade ceramic material perfect for heavy grinding, weld removal, and deburring of ferrous metal (Steel, Stainless Steel, Cast Iron, Carbon Steel). Precision-engineered bi-directional tape joint will prevent clogs while anti-clogging stearate will reduce heat buildup, and resin bonding reduces belt wear.

Top benefits of Sackorange Grinding Belt

Sackorange Belt is the perfect tool for heavy grinding. Wear down steel casings quickly. The belt’s premium material provides you with an easily affordable metal grinding sanding belt that will not only accomplish your goal but do so in half the time it would take if you were using any other abrasive materials or tools. This product is also made to last longer than competing products because of its durability and built-in features. If you’re looking for a durable, dependable option, then look no farther than Sackorange Metal Grinding Sanding Belt today!

It does what it promises to do – grinds metal efficiently and quickly; secondly, its quality construction will stand up to the task at hand, and thirdly, it’s reasonably priced.

Pros

- Grinds metal efficiently and quickly

- It’s made of a durable material that will not wear down easily

- Anti-clogging features reduce heat buildup and resin bonding reduces belt wear which prolongs the life of the sander

Cons

- Non-durable

- High risk of malfunctions

Final Words

Sackorange Metal Grinding Sanding Belt is an excellent buy for any shop or company that requires efficiency and performance from their tools! The benefits of this product are numerous: firstly, it does what it promises to do – grinds metal efficiently and quickly; secondly, its quality construction will stand up to the task at hand, and thirdly, it’s reasonably priced.

MultiTool Belt Grinding Attachment

Outfitted with two high-performance belts and the ability to swap out either without tools, your MultiTool Grinding Attachment can seamlessly transition from one type of material to another. Autoset and AC/DC capability ensure that you don’t need any clamps or switches for this device. An all-metal construction lends extra security to an already dependable machine.

Grinding and sanding can be frustrating and challenging, but luckily we have the MultiTool Belt Grinding Attachment. Versatile and heavy-duty, this belt grinder is capable of grinding on a rubber contact wheel as well as the flat paten, disc, or free-strapping. This means that you can grind any position in between vertical and horizontal, making it easy to get the job done right the first time! Save some time with this quality attachment today.

This belt grinding attachment is perfect for those who want to take your repairs from good to great. The running position of the belt is simple to adjust, and it stays there, allowing you a quality finish on each part. It is designed with a high-quality alloy steel material that won’t break or rust easily, even in damp environments.

The MultiTool Belt Grinding Attachment is the ultimate attachment for taking your polishing to the next level. Loaded with features, this belt grinder provides an above-average 8000 RPM to give you a super-smooth surface!

Top benefits of MultiTool Belt Grinding Attachment

The MultiTool Belt Grinding Attachment is a durable and long-lasting attachment that will not need to be replaced or repaired quickly. This means you save time when replacing the belt because it only takes under 5 seconds, increasing your productivity.

Pros

- Durable and long-lasting

- No need to change belts manually

- Easy belt changing in under 5 seconds

Cons

- Drive wheel not true and caused too much vibration

Final Words

It’s versatile enough for any type of grinding job, from polishing to sanding, so there isn’t much this tool can’t do! If you’re looking for an attachment that can get the job done quickly while saving time with simple maintenance, then pick up one today!

Tips for Using Your Sanding Belt

The first thing that you should do is make sure that the abrasive side of the sanding belt faces outwards if it can move around or spin freely. This will allow you to get more efficient results while cutting, so you won’t have to worry about it getting stuck on the machine or moving out of place.

The next thing that you should do is wear protective gloves when using sanding belts. They work by flaking off pieces of themselves as soon as they start to cut, so it’s straightforward for them to get caught in your fingers, break off and even cause some pretty deep cuts.

The third thing you need to do is wear a dust mask if your belt starts to produce a lot of dust. That’s the last thing you want to fill up your house or get into your clothes and hair!

Finally, you must get rid of any leftover pieces once you’re done using the sanding belt. They’re tiny, so they can easily get lost, but they can also be harmful to your lungs if you breathe them in.