Base widths are available in 4″, 6″, 8″, 10″ and 12″. Select DS – Shipment in three to five weeks. Widths to 16″. Lengths in 1″ increments to 64″.Standard dovetail-slide sets range from a couple inches to 20 in. wide with saddles to 36 in. long, and bases to 96 in. or longer in some cases.

What size are standard dovetails?

Dovetails come in several different types and sizes depending on manufacturer, but the most common are the 11 mm and 3⁄8 inch (9.5 mm). Some other less known, but currently commercially available dovetail mounts, are 12, 13, 13.5, 14, 14.5, 16, 16.5, 17 and 19 mm.

How deep should sliding dovetail be?

Sliding dovetail cutter selection: If it is a full-width joint, the slot depth-of- cut should be no more than 1⁄3 of the board thickness, so as not to significantly weak- en the board.

What is the tolerance for a dovetail slide?

RE: DOVETAIL DIMENSIONING You apply a profile tolerance of 0.5mm and an angular tolerance of 0.1mm.

What is the angle of a dovetail slide?

Angles used on dovetails On large industrial scale machines the angle is usually 45º. For smaller dovetails the usual angle is 60º. Any less than this, i.e. 60° on a small machine, complicates the design of the adjustment mechanism. The angle produced is set by the dovetail cutter used.

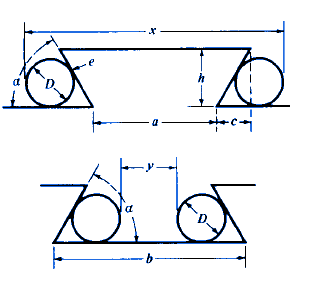

How do you dimension a dovetail?

To obtain dimension x for measuring male dovetails, add 1 to the cotangent of one-half the dovetail angle α, multiply by diameter D of the rods used, and add the product to dimension α.

What are the disadvantages of a sliding dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

Are 3 8 and 11mm dovetail the same?

The 3/8 Inch is measured across the bottom of the dovetail whereas the 11 mm is measured across the top of the dovetail. A 3/8 Inch dovetail is about 12.7 mm across the top. The measurements 3/8 and 11mm are not the same for this reason plus the angles are different.

What are the rules for dovetail?

RULES: Dovetail is a better ball stroke play game played with a partner, with each player having their gross score recorded on a minimum of 8 holes. Both partners play the holes individually to the stroke play format and then select which score is entered on the card.

Why is the dovetail slide widely used in engineering?

“A dovetail slide is used more for positioning, usually not high cycling,” said Dale Blank, Engineering Supervisor at Gilman Precision. “A dovetail slide is easier to lock up because of the angles on the dovetail. If you want to position something and lock it tight, a dovetail would be a good fit for that application.”

What is the best angle for a slide?

Calculations. There are guidelines for the safety standards behind every slide. The simple rules are that the overall angle from top to bottom must not exceed 40 degrees. 35 degrees is more normal, 40 is a little steep.

What is the strongest angle for a dovetail?

Any angle between 7° and 15° will work, regardless of the wood. But stay within that range. If you go below 7°, you’ll start to lose the mechanical strength of the dovetail. Go above 15°, and you’ll leave too much short grain at the tips of the tails, which weakens the joinery.

What is the minimum angle for a slide?

The target angle for fun and safety is between 30-45 degrees. According to the CPSC Playground Safety Handbook and ASTM F1487-11, an embankment slide should be designed to an average angle of 30 degrees and it must not exceed 50 degrees at any point.

Is 11mm and 3 8 dovetail the same?

The 3/8 Inch is measured across the bottom of the dovetail whereas the 11 mm is measured across the top of the dovetail. A 3/8 Inch dovetail is about 12.7 mm across the top. The measurements 3/8 and 11mm are not the same for this reason plus the angles are different.

What is the most common dovetail ratio?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What size is a through dovetail joint?

Through Dovetail Wood Joints have 2 to 4 joints and full joint depths. Wood joints are typically used in wood members with widths between . 75”-1.5” (1.9-3.8 cm) and depths between of 1.5”-3.5” (3.8-8.9 cm).

How thick should a dovetail jig be?

Dovetail Jig rave about the user-friendly features. The jig’s patented alignment lines and router bit-depth stop simplify set up and get you up and running in no time. This versatile jig accepts stock from 1/4 to 1-1/8 inch in thickness and up to 12 inches in width.

How tight should dovetails be?

If you can use your fist as a hammer to nudge them together, they’re just right. By the way, when you realize they will fit nice and snug, (hopefully by the time they are less than half way down) take them apart and don’t put them together again until you glue them.

What is a dovetail slide?

Dovetail slides are a cost-effective slide solution for many light to medium-duty applications; such as assembly, test, gage, motion control, and machine applications. Dovetail slides feature cast iron construction. They are ruggedly built and available in a wide variety of popular sizes and styles.

How do dovetail slides work?

How Dovetail Slides Work. The moving part of the system is secured into the V-shaped groove and makes direct contact with the load in a dovetail slide. Dovetail slides can hold and move a bigger load because their surface area is often larger than a ball-bearing linear or roller slide.

Should dovetail joints be glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

When did they stop using dovetail?

According to oldcopper.org, coppersmiths kept on dovetailing the seams until about 1900, after which better joinery technology made the time-consuming dovetail process obsolete. This means that a dovetailed pot or pan could have been hand-cut or machine-cut.

What is the most popular dovetail?

1) Through Dovetail Also known as the plain dovetail, this is the most common and basic type of dovetail joint. Through interlocking tails and pins, this joint showcases consistent angles, revealing the wood’s end grains on external surfaces.

What is the difference between English dovetail and French dovetail?

English dovetails are the most common. They have interlocking joints and allow the most amount of space – usually several more inches of room than you would get with French dovetails. This is because the dovetail groove cannot be put all the way at the edge of a drawer with French dovetails.

What is a standard dovetail?

A series of pins cut to extend from the end of one board interlock with a series of ‘tails’ cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.