Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

What is the standard size of a dovetail?

11 mm and 3/8” dovetails are the two most common types of dovetails that you can find on rifles. The 11 mm dovetail represents a standard in Europe, while the 3/8” is a standard in the USA.

How thick should a dovetail jig be?

Use the jig to cut half blind dovetails for drawer construction, as well as precise comb or finger joints. Cutting up to 28mm thick material, the jig is ideally suited to utility furniture. It will also cut through dovetails, in material up to 19mm which is great for projects such as toolboxes.

What are the rules for dovetail joints?

The ‘pins’ are the bits of wood between the tails so there are two half-pins; one each side. The general rule is that they measure half the thickness of timber plus around a mm, so the two dots on the shoulder line are 7mm in from each edge.

What is a 11mm dovetail rail?

Description. This 11mm dovetail rail attaches to the receiver of Savage MKII rifles to allow the use of Gehmann, Anschutz, or other rear sight options. This is the same rail included with our complete biathlon sight set for the Savage rifles.

What is the common dovetail ratio?

Anything from 1:6 to 1:9 looks good and works well. Too little rise leaves corners with short grain that easily breaks off, too much rise looks like a poorly made box joint. As long as it looks good, and assembles without breaking, its a good joint.

How strong is a dovetail joint?

The dovetail joint is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

Is a dovetail joint strong or weak?

Dovetail joints are very strong by design and they also offer an attractive finish that is a true sign of craftsmanship. Professionally cut and glued dovetail joints are virtually impossible to separate.

What are the weaknesses of dovetail?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

Should you glue dovetail joints?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

What are the dimensions of a dovetail slide?

What is the best length for a dovetail saw?

Even if you’ll use your saw mostly for run of the mill drawer dovetails, the longer length will give much straighter cuts, and be much faster. It will also help you to see square. Go for around the 10″ (250mm) mark. Maybe a little longer if you work thicker stuff.

Are all dovetail sights the same size?

Types of Dovetail Sights There are four main types of dovetails. Each style of dovetail (i.e. GI, Novak, Bomar, LPA TRT etc.) have a different dovetail degree and size. Essentually this means you will have to choose the correct sight to fit your existing dovetail, or mill the slide to accept a new style.

What is a 6 to 1 dovetail?

The left-hand photo shows the “ratio” method to layout the angle of your dovetails. (I used SketchUp to draw and show the angles.) A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle.

Is Picatinny better than dovetail?

Chiefly Picatinny mounts are made from a single piece of metal, which makes them stronger and more durable than dovetail mounts, which are traditionally made from two pieces of metal welded together. Picatinny mounts also have a wider rail, which makes them more stable and less likely to shift when you’re shooting.

Why is it called dovetail?

Dovetail joints are made up of two parts called pins and tails. When a master craftsman wants to marry two boards together, they cut a series of pins on one board and matching tails on the other. They are trapezoidal in shape, resembling the tail feathers of a dove (hence the name dovetail).

What is the formula for measuring dovetails?

To obtain dimension x for measuring male dovetails, add 1 to the cotangent of one-half the dovetail angle α, multiply by diameter D of the rods used, and add the product to dimension α.

Which of the following is the most basic dovetail joint?

The through dovetail joint, alternately called the plain dovetail, is the most basic of its kind. This type of dovetail uses a method that resembles interlocking fingers. Crafters achieve this look by joining join two pieces of wood together by interlocking the pins and the tails.

What is the most popular dovetail joint?

The through dovetail joint is the most popular dovetail joint because it is strong, attractive, and versatile. It is commonly used in furniture-making, cabinetry, and woodworking. The through dovetail joint is a traditional woodworking joint characterized by the interlocking triangular shape it creates.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

Is dovetail the highest quality?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

What is stronger dovetail or finger joint?

For box joint, some people put a lot more fingers than it is possible to do with Dovetail. In this case, the gluing surface is larger, and the joint is likely stronger. Also, some find a way to hide a finish nail in the joint. Dovetail has the advantage of a mechanical lock independent of the glue.

What is an alternative to a dovetail joint?

The finger joint resembles a dovetail joint in the way that both boards mesh together and create a visually appealing pattern when the joint is assembled, but the finger joint is significantly easier to master.

Can you make dovetail joints with plywood?

A wide variety of methods can be used to make dovetail plywood drawer boxes. They are generally considered by the woodworking industry as time-consuming and difficult to make. The dovetails can be cut by hand with a dovetailing saw and chisel or you can use a dovetail jig and router.

What is the common angle for a dovetail joint?

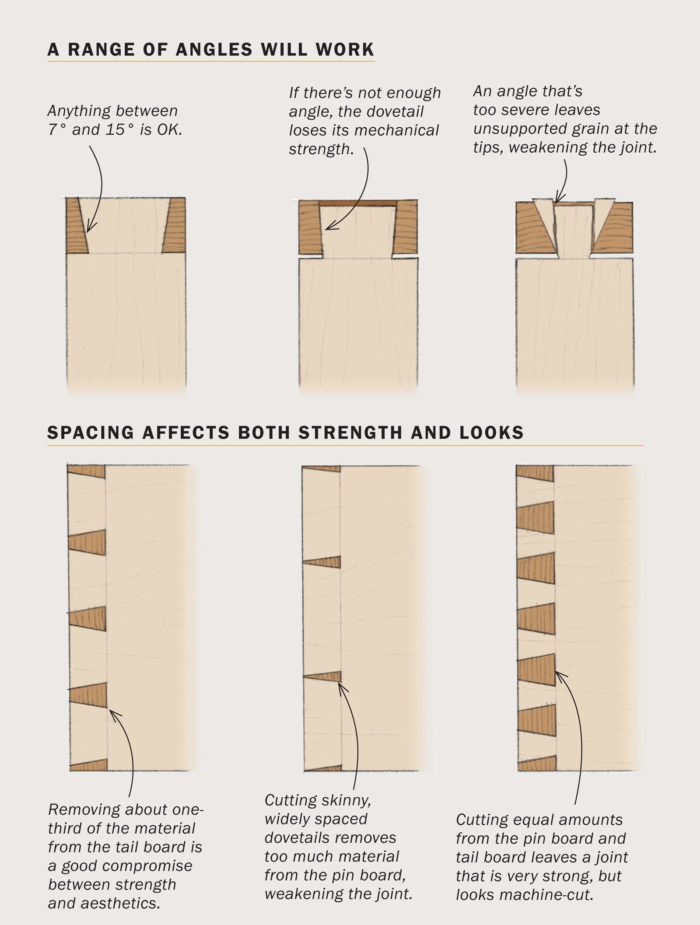

Although softwoods are more compressible than hardwoods, you needn’t change the dovetail angle to add strength to the joint. Any angle between 7° and 15° will work, regardless of the wood. But stay within that range.