you; we recommend at least 8mm shanks, but 1⁄2″ would be even better, with of course the appropriate guide- bush. If you have to use 1⁄4″ shanks in hardwood, use a second router to rough out the slot centre with a straight cutter. We recommend 5⁄8″[15,9mm] as the min- imum size guidebush for sliding dovetails.

How thick should dovetails be?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

How thick should a dovetail jig be?

Material capacity: 300mm width, 6–28mm dovetail thickness.

What is the standard size of a dovetail?

Through Dovetail Wood Joints have 2 to 4 joints and full joint depths. Wood joints are typically used in wood members with widths between . 75”-1.5” (1.9-3.8 cm) and depths between of 1.5”-3.5” (3.8-8.9 cm).

What are the rules for dovetails?

RULES: Dovetail is a better ball stroke play game played with a partner, with each player having their gross score recorded on a minimum of 8 holes. Both partners play the holes individually to the stroke play format and then select which score is entered on the card.

How thick should dovetails be?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

Can you put dovetails in plywood?

A wide variety of methods can be used to make dovetail plywood drawer boxes. They are generally considered by the woodworking industry as time-consuming and difficult to make. The dovetails can be cut by hand with a dovetailing saw and chisel or you can use a dovetail jig and router.

Should dovetail joints be glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

Why are my dovetail joints loose?

DTs should go together with a firm tapping. If they are too hard to tap together, they will split or crack; too lose and they will have unsightly gaps. The strength of the joint is largely mechanical. I use yellow glue to assemble mine; I’ve never had one fail from being glue starved.

Can I make my own dovetail jig?

All you need is some standard, off-the-shelf hardware, 5 board feet of hardwood , and a piece of hardboard to make your own “comb” template. However, as I got into the project further I found some improvements I could make over manufactured dovetail jigs along the way.

What is the most common dovetail ratio?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

Is dovetail 11mm?

Dovetails come in several different types and sizes depending on manufacturer, but the most common are the 11 mm and 3⁄8 inch (9.5 mm). Some other less known, but currently commercially available dovetail mounts, are 12, 13, 13.5, 14, 14.5, 16, 16.5, 17 and 19 mm.

Is 11mm and 3 8 dovetail the same?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

Can you cut dovetails with a jigsaw?

If you have a jigsaw table, a few simple angle jigs can help you create fast, precise and repeatable dovetails.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

What is a good ratio for dovetails?

D) MARK DOWN TO YOUR MARKING GAUGE LINE Now it’s time to decide on a dovetail ratio, or angle. If you have one of my dovetail jigs, you can skip ahead to Step 4. Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1).

What size dovetail chisels do you really need?

The next most used would be a 3/4″. I use the 1/4″ for groove, dado and mortise chopping/cleanout as well as dovetail corner work. I use a 1/2″ chisel for general chopping/paring/cleanout quite often as that size offers a good combination of ease of chopping and width of cut (progress made).

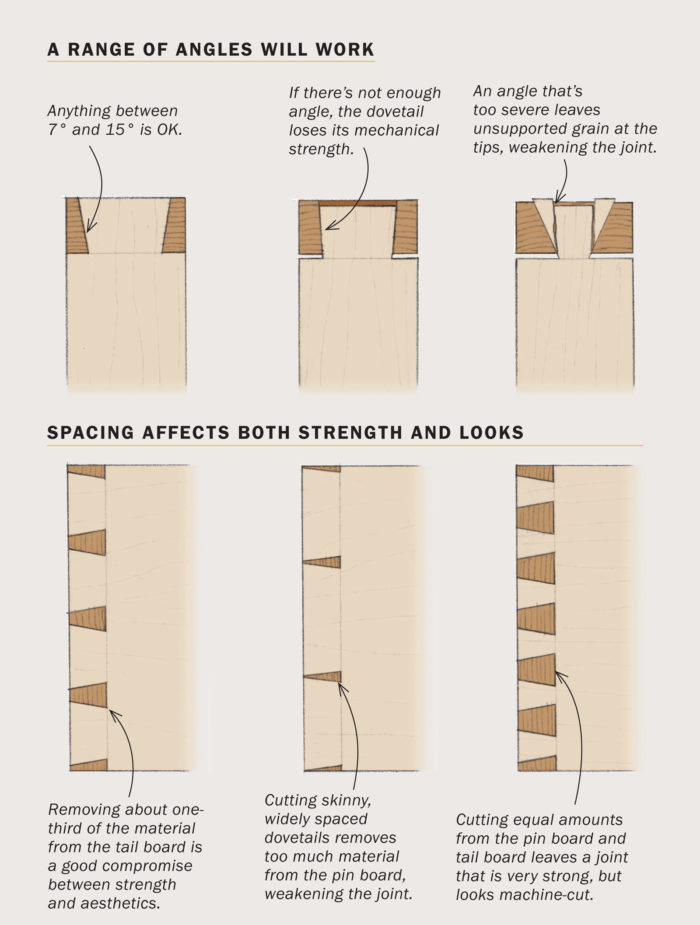

What is the ideal dovetail angle?

Lower (7° to 9°) angles are often advised for joining hardwoods, while higher angles (10° to 14°) are recommended for softwoods and even higher angles (14° to 18°) for half-blind dovetails.

What ratio is a 14 degree dovetail?

There is no hard and fast rule when it comes to dovetail angles. Commonly accepted ratios are 1:8 for hardwoods and 1:6 for softer timber. This 14° marker equates to a ratio of 1:4.

How thick should dovetails be?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

Can you cut dovetails with a jigsaw?

If you have a jigsaw table, a few simple angle jigs can help you create fast, precise and repeatable dovetails.

Can I use pine for dovetails?

Pine. While pine is commonly used as drawer sides, it’s not the best to practice good dovetail technique with. You need scary sharp chisels just to pare it properly.

What is the easiest wood for dovetails?

Pine could actually be TOO SOFT to practise on. You need super sharp chisels to pare it well. Poplar is usually the right price for such endeavours but usually whatever you have laying around wouldn’t be a bad start. Try some plywood, too.

What wood is best for dovetails?

For practicing hand cut dovetails, poplar hardwood is very good as it is much finer than pine, it is forgiving, easy to saw and compressible. Once you have mastered the hand cut dovetail, you can move on to harder woods for the drawer sides. The drawer front should be harder regardless.

What is the weakness of dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.