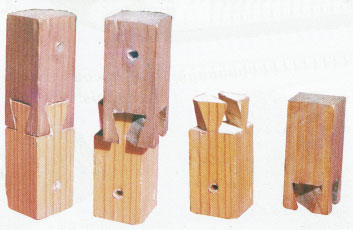

The answer is that when the dovetails are cut and each one joined, not to its partner on the opposite side but to a dovetail on one of the surfaces at right-angles to it. This makes it possible to slide the joint apart quite easily by pushing the two halves diagonally in opposite directions.

What is an impossible dovetail?

Press a dovetailed board into another board with matching sockets, and you’ve created woodworking’s most iconic joint. The dovetails and sockets wedge the boards together, so the joint can’t pull apart; the only way to disassemble it is to lift the dovetailed board back out of the sockets.

What is a hidden dovetail joint?

Hidden dovetails are really no different that standard dovetails aside from the fact that you cut each half of the joint only part way through. The remaining material is used to conceal the pins and tails, while also forming the miter itself.

What is the weakness of dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

Is dovetail the strongest joint?

Strength. Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint.

What is stronger dovetail or finger joint?

Frid wrote that finger (or box) joints are stronger than through dovetails because the fingers offer much more glue surface.

What is the strongest joint in woodworking?

Mortise and tenon joints have stood the test of time for their remarkable strength. This traditional joint involves a projecting piece of wood, called a tenon, securely fitting into a corresponding cavity, a mortise. It can be reinforced with glue or wedges for stability for a stronger hold.

What is an English dovetail joint?

English Dovetail / Through Dovetail The craftsperson usually orients the tails and pins in this joint horizontally, although this isn’t a cardinal rule. It is sometimes called a through dovetail because both the pins and tails go all the way through each-other.

How deep should a dovetail joint be?

With a 3⁄4″-diameter flush-trimming bit in your router, plow out the dado to 3⁄16″ deep. Next, take your router with a tem- plate guide and dovetail bit, set it to 9⁄16″ deep (without moving the straightedge) and make the cut into the case side. The cut should be a bit longer than the width of your front divider.

What is a French dovetail joint?

Fyi, the English dovetail technique is also commonly referred to as a butt joint. French Dovetail: This technique is based on cutting out a slat in the middle of a board and also a corresponding piece of wood that can slide into the middle cutout. English and French Dovetail Drawer Construction.

What is the difference between English dovetail and French dovetail?

English dovetails are the most common. They have interlocking joints and allow the most amount of space – usually several more inches of room than you would get with French dovetails. This is because the dovetail groove cannot be put all the way at the edge of a drawer with French dovetails.

Are dovetail joints worth it?

Making sure that you pick a drawer joint that can withstand this type of wear and tear is crucial to the longevity of your kitchen cabinets. Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

What is the weakest joint in carpentry?

The butt joint is the simplest joint. An unreinforced butt joint is also the weakest joint, as it provides a limited surface area for gluing and lacks any mechanical interlocking to resist external forces.

Which is the weakest carpentry joint type?

A butt joint uses a simple technique whereby two pieces of material are joined together at their ends, without any special shaping or cutting. Although it is simple, the butt joint is also the weakest of the wood joinery types.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

What are the different types of dovetail rails?

Dovetails come in several different types and sizes depending on manufacturer, but the most common are the 11 mm and 3⁄8 inch (9.5 mm). Some other less known, but currently commercially available dovetail mounts, are 12, 13, 13.5, 14, 14.5, 16, 16.5, 17 and 19 mm.

What does it mean when you dovetail?

dovetail | Intermediate English to fit together well, or to cause something to fit together well with something else: [ I ] Our plans dovetailed, and we were able to meet that evening.

What is a dovetail on a gun?

Commonly used on rimfire rifles and air guns, the dovetail mounting system features two grooves that run parallel to the bore. Also called a “tip off” mount, the dovetail rail allows the shooter to easily remove and replace mounted optics.

What does dovetail mean in dentistry?

A cavity whose shape is flared, created to provide a retentive lock for a direct or indirect restoration. From: dovetail in A Dictionary of Dentistry »

What is half blind dovetail?

In half-blind dovetails, the tails are embedded in the pins board without going all the way through. They give you the strength of regular dovetails with uninterrupted grain on one side, which is why they’re often used for drawers.

Do dovetail joints need glue?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

What is the strongest end joint?

MORTISE AND TENON JOINT Mortise and tenon joints are widely regarded as one of the strongest and most reliable woodworking joints. They involve creating a mortise, or a hole, in one piece of wood and a tenon on the end of the other piece, which fits into the mortise.

Are dovetail joints difficult?

Hand-cutting a dovetail joint is kind of a woodworking high-wire act; one slip of the saw or chisel and the joint either won’t fit together or will look sloppy. It takes a lot of time to master the ability to cut dovetails quickly and well (by hand or machine), without a lot of fussing around.

What is the best dovetail angle?

The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods. One Wednesday morning I laid out and cut a bunch of these dovetails. I ignored the really shallow angles (6.5° to 8.5°) because I wanted to adopt something more angular. The 10° dovetails looked OK.

What is the best joint for joining timber end to end?

Finger joints provide face- or edge-grain gluing surfaces to end-to-end joints for a stronger glue bond. Any joint that butts end grain to end grain will be weak because you’re gluing wood fibers at their porous ends instead of along their sides.

Is mortise and tenon the strongest joint?

One of the most common and strongest joints is a mortise and tenon joint, an extremely old woodworking technique that has stood the test of time and is still used today. In its most basic form, a mortise and tenon joint is simple, extremely strong, and the technique can be scaled up or down in size with great success.