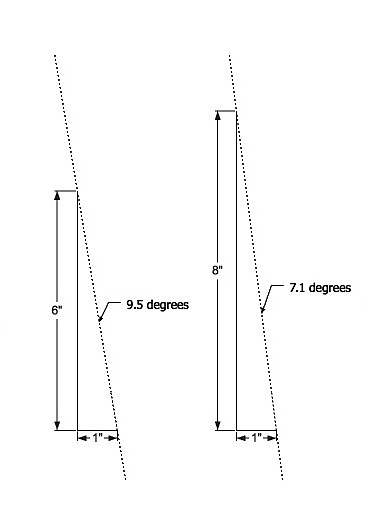

A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle. A 1:8 ratio – one unit horizontal with eight matching units drawn vertical – is an angle of 7.1 degrees.

What ratio is a 14 degree dovetail?

There is no hard and fast rule when it comes to dovetail angles. Commonly accepted ratios are 1:8 for hardwoods and 1:6 for softer timber. This 14° marker equates to a ratio of 1:4.

What is the ratio of a dovetail to an angle?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What degree angle is a dovetail?

The angle of a dovetail joint should be between 7 and 15 degrees: too broad and the joint won’t be strong enough, too skinny, and the pin can snap. So the angle of the dovetail mainly depends on the use and wear the joint will get. Diagram showing dovetail angles vs strength from Fine Woodworking.

What are the measurements for a dovetail?

Fine work the pins 4mm > 6mm, larger work 7mm > 12mm. To have a desirable appearance the pins smaller than the tails. Your tails should be around 18mm > 35mm for fine work like drawers and 35mm > 55mm on larger work like a chest. Decide on your tail size remembering “One more tail than pin”.

What is the strongest angle for a dovetail?

Any angle between 7° and 15° will work, regardless of the wood. But stay within that range. If you go below 7°, you’ll start to lose the mechanical strength of the dovetail. Go above 15°, and you’ll leave too much short grain at the tips of the tails, which weakens the joinery.

What is the most common dovetail angle?

Percy Blandford, who has been writing about woodworking for a long time, writes in “The Woodworker’s Bible” that any angle between 7.5° and 10° is acceptable. The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods.

What is the angle of a 11mm dovetail?

The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

What is the ratio of tail to pin in a dovetail joint?

The line between that end point and starting point will be the angle of your tail and pin sides. 6:1 (9.5°) and 8:1 (7.1°) dovetail ratios are the most common (though you’ll often see 4:1 and 10:1 as well).

What is a 3 8 dovetail?

3/8″ dovetail rails, sometimes call tip off rails, consist of two thin parallel grooves and are used almost exclusively on rimfire rifles and air rifles. 3/8″ dovetail rails are a common, standardized style within the rimfire industry and are inexpensive to machine into the firearm’s frame.

What is a standard dovetail?

A series of pins cut to extend from the end of one board interlock with a series of ‘tails’ cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

Is 11mm and 3 8 dovetail the same?

The 3/8 Inch is measured across the bottom of the dovetail whereas the 11 mm is measured across the top of the dovetail. A 3/8 Inch dovetail is about 12.7 mm across the top. The measurements 3/8 and 11mm are not the same for this reason plus the angles are different.

How many mm is dovetail?

Dovetails come in several different types and sizes depending on manufacturer, but the most common are the 11 mm and 3⁄8 inch (9.5 mm).

What degree is 1 8 dovetail?

A 1:8 ratio – one unit horizontal with eight matching units drawn vertical – is an angle of 7.1 degrees.

What is the angle of a 1 8 dovetail in degrees?

It would be extremely difficult to be able to pick these differences up in your dovetails on a piece of furniture by eye. So in closing your 1:4 Saddle-Tail is for all practical purposes 14 degrees, the 1:6 is close to 10 degrees and the 1:8 is about 7 degrees.

What is the ratio of pin to tail for dovetail joints?

The line between that end point and starting point will be the angle of your tail and pin sides. 6:1 (9.5°) and 8:1 (7.1°) dovetail ratios are the most common (though you’ll often see 4:1 and 10:1 as well).

What are the typical angles of dovetail markers?

Percy Blandford, who has been writing about woodworking for a long time, writes in his new book, “The Woodworker’s Bible,” that any angle between 7.5° and 10° is acceptable. The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods.

What is the most popular dovetail joint?

Single-lap Dovetail The single-lap (known to many folks as a half-blind dovetail) is the best known of the dovetails since it’s used to join the front to the sides of a drawer.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

What rifles have 11mm dovetail?

Are weaver and dovetail the same?

Also called a “tip off” mount, the dovetail rail allows the shooter to easily remove and replace mounted optics. Although dovetail rails come in a variety of sizes, the most common are 11mm and 3⁄8 inch (9.5 mm). Developed by William Ralph Weaver, the Weaver rail was created in an attempt to standardize scope mounts.

What are the rules for dovetail joints?

The general rule is that they measure half the thickness of timber plus around 1 mm along the shoulder line. So these two awl dots are 7 mm in from each edge. These two dots, which mark the corners of the half pins, are now converted into a 1:8 slope at each side.

What is the difference between a pin and a tail dovetail?

There are two parts to a dovetail joint, pins and tails. The tails look like the tail of a dove (hence the name), and the pins are on the opposite board and fit in between the tails to create a joint that is impossible to pull apart in at least one direction.

What is an English dovetail joint?

Is dovetail the strongest joint?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

What is the strongest joint in woodworking?

A mortice and tenon joint is generally recognised as the toughest around.