Finger jointed material is glued together end to end which can create faults over time at some joints, particularly if the deck is in an area exposed to weather conditions, receives a lot of traffic or heavy furniture is placed on the deck.Disadvantages of using finger joints:

Time-consuming: Finger joints can be quite time-consuming to make. …

Limited use: Finger joints are not suitable for all types of woodworking projects. …

Limited flexibility: Finger joints are not as flexible as other types of joints. …

Limited strength for certain types of wood: In some cases, finger joints may not be the best choice for certain types of wood. …

What are the disadvantages of finger joints?

One potential issue with finger joints is that they can be difficult to sand or plane. This is because the joint is made up of a series of interlocking fingers, which can make it challenging to get a smooth, even surface.

Is finger joint wood strong?

Finger joints are just as strong as the longer strips of wood. And in terms of joints, finger joints are as strong as—in some cases stronger than—the fabled mortise and tenon after you apply adhesives.

Are finger joints strong or weak?

The finger joint design is usually based on a desire to achieve high strength. Best strength performance seems to be achieved with a slope of 1 to 12, with a thin tip of 0.01 in. (but not so sharp or not so thin as it may break in handling), and a base or root width (sometimes called the pitch) of 0.3 in.

What is a major defect in a finger joint woodworking?

Here’s some common problems, causes and solutions for fingerjointing. 1: Pressed fingerjoint blanks fall apart. Probable causes: (1) Glue penetration into wood is not adequate. (2) Temperature is too cold to allow glue to form a reliable bond and chalking occurs.

What are the disadvantages of finger joints?

One potential issue with finger joints is that they can be difficult to sand or plane. This is because the joint is made up of a series of interlocking fingers, which can make it challenging to get a smooth, even surface.

Is finger joint wood strong?

Finger joints are just as strong as the longer strips of wood. And in terms of joints, finger joints are as strong as—in some cases stronger than—the fabled mortise and tenon after you apply adhesives.

What is the weakest wood joint?

A butt joint is the easiest of all simple wood joints, but also is the weakest. The cut end of one board butts up against the edge of another piece at a right angle. The key to every type of wood joint is having smooth, square cuts on the boards, and the butt joint is no exception.

What is a joint problem in the finger?

Sudden pain and swelling in your finger joints can be a result of an injury, infection, or systemic conditions like RA, PsA, lupus, and gout. The pain and swelling that occur are usually due to the inflammation caused by these conditions.

Is finger joint wood waterproof?

So basically, finger joint panel has similar characteristics to solid natural wood. Therefore, the waterproof ability of finger joint board is extremely good.

Is MDF better than finger joint?

Although MDF is stronger, it is more difficult to repair if dents or marks are made on the material. Finger jointed pine is slightly more expensive than MDF. As it is a natural timber material, it is softer than MDF and can be more susceptible to marks.

Can you stain finger jointed wood?

Finger joint pine is planed to a smooth finish and is perfect for priming and painting, as well as staining or varnishing if you want to take advantage of the natural wood grain and show it off as a feature in your home.

Is finger joint wood better than solid wood?

Finger Joint Board Strength & Durability There is no negative impact on structural integrity or durability. Finger joints are just as strong as the longer strips of wood. And in terms of joints, finger joints are as strong as—in some cases stronger than—the fabled mortise and tenon after you apply adhesives.

What is the strength of a finger joint?

Finger-jointed lumber and timber can be fabricated to have 75% of the strength of clear wood (FPL 1999), and has been an indispen- sable material for a variety of engineered structural products. A finger joint is one configuration used to join wood.

What are the weakest joints?

Synovial joints are the only joints that have a space (a synovial cavity filled with fluid) between the adjoining bones. The presence of synovial fluid and an articular capsule give synovial joints the greatest range of movement among the three joint types; however they are the weakest of the joint types.

What causes finger joints to deform?

Joint deformity can occur in any joint in the body. It commonly affects the hands and feet. It can happen for various reasons. Joint deformity can be due to OA, RA, fractures and injury, lupus, bone or cartilage cancer, and osteomyelitis.

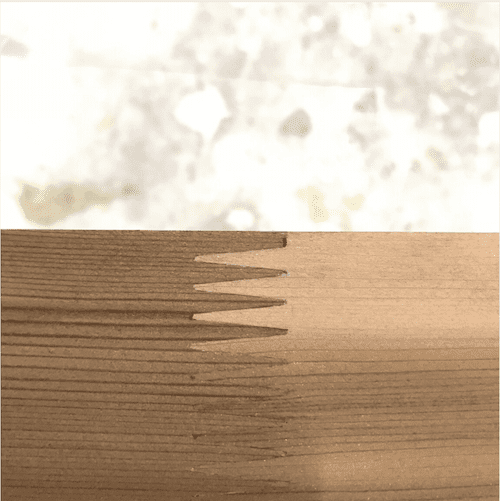

What does a finger joint look like wood?

Finger jointed timber is a type of wood process made by joining pieces of wood together to form a longer piece or large volume of a desired length. The pieces are cut at an angle, creating finger-like projections that interlock with each other. The joints are then glued to create a solid, seamless pieces of wood.

What are the advantages of finger jointing?

Finger jointing results in much higher quality and stronger pieces and components, while dramatically reducing waste in our industry where the cost of raw materials is rapidly increasing. The two most important advantages of finger jointed lumber are straightness and dimensional stability.

What are the advantages and disadvantages of method of joints?

Advantages of the method of joints: simple, no moments considered. Disadvantages of the method of joints: slow and computationally expensive for large trusses (even if you need forces in just one or two members). To overcome the difficulty, another method is used often: Method of Sections.

What is the advantage of fingers?

In humans, the fingers are flexibly articulated and opposable, serving as an important organ of tactile sensation and fine movements, which are crucial to the dexterity of the hands and the ability to grasp and manipulate objects.

What are the disadvantages of finger joints?

One potential issue with finger joints is that they can be difficult to sand or plane. This is because the joint is made up of a series of interlocking fingers, which can make it challenging to get a smooth, even surface.

Is finger joint wood strong?

Finger joints are just as strong as the longer strips of wood. And in terms of joints, finger joints are as strong as—in some cases stronger than—the fabled mortise and tenon after you apply adhesives.

What is the most difficult woodworking joint?

Found frequently on drawers, the dovetail joint is the Holy Grail of woodworking joints. The wedge-shaped pins and tails are cut on mating pieces which resist being pulled apart. The dovetail is beautiful and strong, but among the most difficult joints to execute.

What is the strongest woodworking joint?

Mortise and tenon joints are widely regarded as one of the strongest and most reliable woodworking joints.

What is the hardest joint in carpentry?

The dovetail joint is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

Can damaged finger joints be repaired?

Joint replacement is used when the joints in your fingers and hands are injured, damaged, or in a lot of pain due to an illness like arthritis. Joint replacement of the finger is most commonly done when your symptoms are severe or don’t get better with medicine or physical therapy.