After setting up the jig, I installed the recommended dovetail bit and carefully set it to 3/8-inch depth. My jig specifies this depth is measured from the template, not the router base. I set my depth with a combination square so I laid the template on the router base and measured from that surface.How deep should a dovetail joint be? Try to keep the depth of the dovetail groove between 1/3 and 1/2 the thickness of the part. For example, if the gable of a chest of drawers is 3/4″ thick, machine the dovetail groove between 1/4″ and 3/8″ deep. Any deeper and you will weaken the gable too much.

How deep should dovetails be?

But keep in mind that if you machine the dovetail groove across the work piece you will be weakening it because you are removing some of its thickness. Try to keep the depth of the dovetail groove between 1/3 and 1/2 the thickness of the part.

What are the rules for dovetail joints?

The general rule is that they measure half the thickness of timber plus around 1 mm along the shoulder line. So these two awl dots are 7 mm in from each edge. These two dots, which mark the corners of the half pins, are now converted into a 1:8 slope at each side.

How big should a dovetail joint be?

Typically we use 1 ½” – 2” deep dovetails that are about 2” less deep than the joist, and 4” less deep than the girt – but that is just a starting point – the loads and reactions have to be calculated from there.

What is the minimum thickness for a dovetail?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

How deep should dovetails be?

But keep in mind that if you machine the dovetail groove across the work piece you will be weakening it because you are removing some of its thickness. Try to keep the depth of the dovetail groove between 1/3 and 1/2 the thickness of the part.

What is the minimum thickness for a dovetail?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

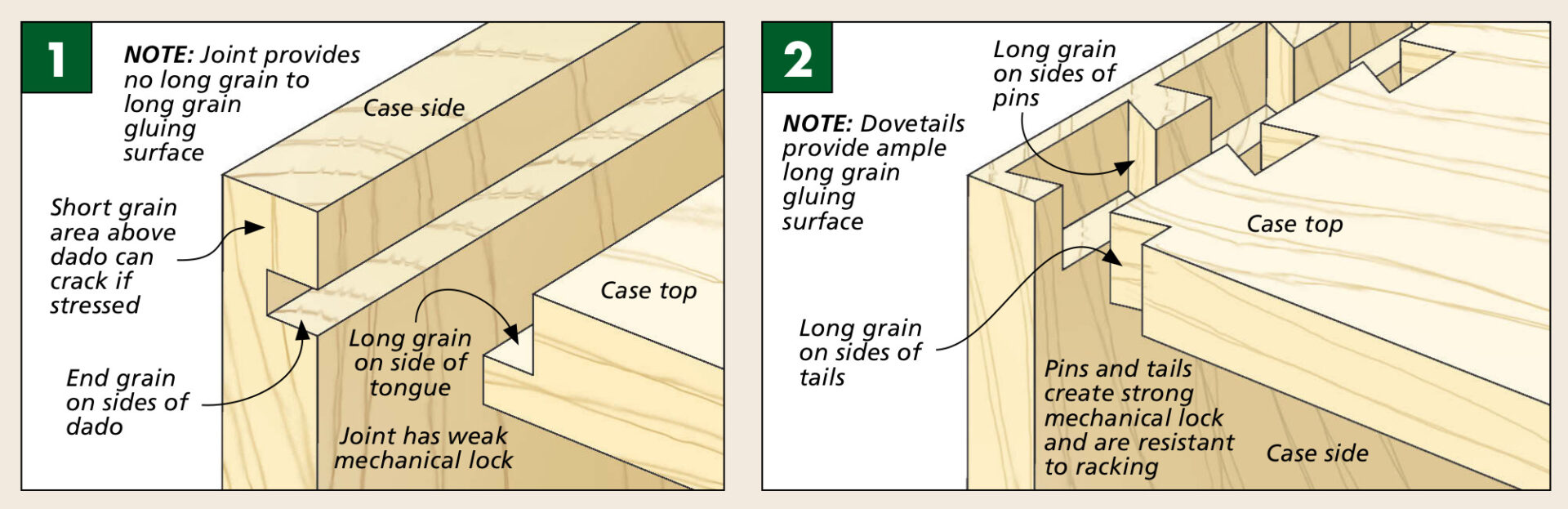

Is a dovetail joint strong or weak?

Dovetail joints are known for their inherent strength and resistance to being pulled apart (tensile strength).

Is dovetail the strongest joint?

The advantages of the dovetail joint are that it is the strongest of all joints, has a large gluing area, is interlocking, resists being pulled apart, looks attractive, and would hold together even without glue.

Do dovetail joints need to be glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

Are dovetail joints worth it?

Dovetail drawers are known for their durability. The joint’s design provides exceptional resistance to the stresses of heavy items, making them ideal for storing dishes, pots, and pans. The construction of dovetail drawers ensures that they will not come apart easily, even with frequent use.

What is the most popular dovetail joint?

Single-lap Dovetail The single-lap (known to many folks as a half-blind dovetail) is the best known of the dovetails since it’s used to join the front to the sides of a drawer.

How do you calculate dovetail joints?

What is the best angle for a dovetail?

Lower (7° to 9°) angles are often advised for joining hardwoods, while higher angles (10° to 14°) are recommended for softwoods and even higher angles (14° to 18°) for half-blind dovetails.

How many mm is dovetail?

Dovetails come in several different types and sizes depending on manufacturer, but the most common are the 11 mm and 3⁄8 inch (9.5 mm). Some other less known, but currently commercially available dovetail mounts, are 12, 13, 13.5, 14, 14.5, 16, 16.5, 17 and 19 mm.

Is 11mm dovetail the same as 3 8?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

How long should dovetails be?

That said, 3/8” gives me room for a drawer bottom groove and enough meat on the drawer sides to compensate for wear and support to the drawer bottom. I then work out how many tails I want. Usually I like tails to be between 1” and 1 ¼” on projects reliant on dovetails more for strength than aesthetics.

How long should dovetails be?

That said, 3/8” gives me room for a drawer bottom groove and enough meat on the drawer sides to compensate for wear and support to the drawer bottom. I then work out how many tails I want. Usually I like tails to be between 1” and 1 ¼” on projects reliant on dovetails more for strength than aesthetics.

What is a good ratio for dovetails?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

What is the ideal dovetail angle?

Percy Blandford, who has been writing about woodworking for a long time, writes in “The Woodworker’s Bible” that any angle between 7.5° and 10° is acceptable. The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods.

What is a 11mm dovetail rail?

Description. This 11mm dovetail rail attaches to the receiver of Savage MKII rifles to allow the use of Gehmann, Anschutz, or other rear sight options. This is the same rail included with our complete biathlon sight set for the Savage rifles.

How deep should dovetails be?

But keep in mind that if you machine the dovetail groove across the work piece you will be weakening it because you are removing some of its thickness. Try to keep the depth of the dovetail groove between 1/3 and 1/2 the thickness of the part.

What is the minimum thickness for a dovetail?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

What is the weakest joint in carpentry?

A butt joint uses a simple technique whereby two pieces of material are joined together at their ends, without any special shaping or cutting. Although it is simple, the butt joint is also the weakest of the wood joinery types.

What are the disadvantages of a dovetail joint?

Hand cut dovetail joints require precise handsaw and chisel skills, and can be fiddly to mark out and cut. If dovetail joints are poorly made they will lose the advantage of strength and durability.

Are dovetail joints permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint. Glue may be applied to the mating surfaces.