Wood is one of the most widely used resources in workshops, small and large projects and various repairs, so it is not surprising that there are many varieties of glue for this material.

Depending on the practical and aesthetic needs that your project requires, you need to find a product that meets your requirements: strength, flexibility, safety or a good finish are qualities that you should take into account when choosing.

5 Best Wood Glue for Furniture

Elmer’s E7300 Carpenter’s Wood Glue Max – The Good Ol’ Reliable

Sometimes relying on a classic brand product is the best way to play it safe. The Carpenter’s Wood Glue Max by Elmer’s Products reflects the consistency and safety the brand has offered for its 60 years in a good, convenient and powerful enough glue.

Simplicity and effectiveness

This product holds especially well in small household projects, although its strength ensures its effectiveness in more complicated outdoor projects.

It is a high-quality glue, whose formula delivers superior bond strength and stainability, offering easy water clean up.

Also, it is very convenient to apply thanks to its container, in which the lid seals well so that the glue stays fresh for a long time.

The Problems

It is a straightforward product, whose simplicity allows it to be almost problem-free. Almost. It is likely that if you go a little overboard with the quantity, the glue will not have a transparent final appearance, but somewhat opaque or yellowish. Maybe, you wanted it to be more clear instead of natural.

Pros

- Resists heat, water mold, and mildew

- Sandable, paintable

- Non-toxic, no harmful fumes

- Convenient container that allows for a long shelf life

Cons

- Takes a full day to cure completely

- Opaque appearance if applied excessively

Gorilla Wood Glue – The strong glue you can always rely on

The versatile but powerful glue from the wildest brand in the industry is ideal for use on hardwoods, softwoods, and natural wood composites. Being a PVA glue, offers the benefits of an easy-to-use, water-based adhesive, with the holding power Gorilla is known for.

The glue of those who need strong stuff

Gorilla makes sure that its products are suitable for use on projects by any woodworkers, carpenters, and hobbyists, so it passes ANSI/HPVA Type II water-resistance and offers one of the highest strength on the market. So be careful not to accidentally glue your hand to the chair while assembling it.

The problems

Water-based solution adhesives are perishable and so extended storage is difficult. On the other hand, to be as effective as possible, it is necessary to prepare the surface by sanding using higher grit sandpaper.

Pros

- Easy-to-use

- Gorilla holding power ensures strength and durability

- Water-based reduces the risk of exposure to toxicity

Cons

- Once opened, it does not remain functional for too long

- Requires surface pre-preparation to achieve the powerful result

Titebond III Ultimate Wood Glue – Ultimate quality that fits your needs

If you want unsurpassed value in a weather-resistant wood-glue, this might be the product to take. With a strong initial tack for clamp-free gluing, it resists solvents, heat, and mildew for a long-term, reliable bond, from another of the sector’s leading brands.

The balance between strength and flexibility

We found this product especially useful for joints: not too hard or brittle, which could make them separate, and not too soft or gummy, which could make them flex. Like many wood glues, it dries significantly darker than it looks in a liquid state, and the color of the wood comes naturally.

The problems

It really doesn’t offer any relevant problems, beyond, as with almost all wood glues, it shrinks as it dries, so be careful where you apply it!

Pros

- Weather-resistant

- Waterproof

- Strong

- Dries to the color of wood

Cons

- Shrinks as it dries

Gorilla Wood Glue vs Titebond

Titebond Glue is a water cleanup glue that provides a strong initial tack and a 30-minute clamp time. Titebond offers excellent heat resistance and is very easy to sand.

Gorilla Wood Glue is an easy-to-use, water-based adhesive with Gorilla holding power. Gorilla Wood Glue can be used on any type of wood for carpentry or hobby projects. The best glue for furniture repair depends on the type of wood you’re using as well as the project at hand.

Gorilla Wood Glue Features

- This water-based adhesive, made by Gorilla Glue Co., is easy to use and holds well.

- For building, carpentry, or hobby projects using any type of wood

- Requires less than an hour in the clamps, fully dry in a day.

- Passes ANSI/HPVA Type II water resistance

- This glue can be used on hardwoods, softwoods, and composite woods.

Titebond Glue Features

- Wood glue is more powerful than the wood itself and can be used for various purposes.

- Hide glue offers excellent heat resistance and is very easy to sand.

- Launder surfaces while they are still wet

- Instantly gains a stronghold on even hard or oily surfaces and requires only 30 minutes of clamping time

- The item conforms to ASTM D4236, the international standard for wood glue that stipulates that products must be non-toxic and safe to use without harming humans.

Titebond 5004 II Premium Wood Glue – The Titebond’s younger brother

Another somewhat older product from the flagship brand Titebond, the predecessor range to Ultimate is cheap, reliable, and well worth the value and adhesive properties.

Excellent for work in the garden

It offers excellent water-resistance and sandability, ideal for exterior applications, including outdoor furniture, birdhouses, planters, mailboxes, and picnic tables. It is solvent-free, non-toxic, and approved for indirect food contact, which provides confidence and safety for all kinds of situations.

The problems

Titebond II is water-resistant, not waterproof. If you’re looking for a waterproof version, you should try Titebond III, which is, indeed, a bit stronger also.

Pros

- Non-toxic and suitable for indirect food contact

- Good sandability

- Water-resistant

- Cheaper than other products

Cons

- Not waterproof

- Slightly weaker

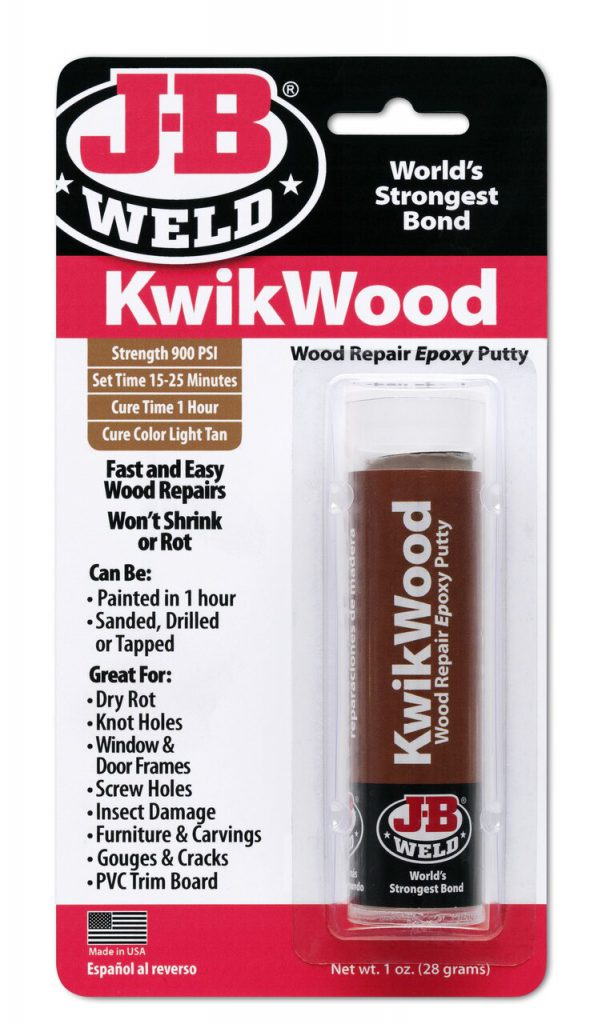

J-B Weld 8257 KwikWood Wood Repair Epoxy Putty Stick – Another way of looking at wood repairing

KwikWood is a hand mix putty designed to repair and rebuild wood. After mixing, it dries to the same density as the wood and becomes an integral part of the repair, making it virtually indistinguishable.

Ultra-fast and innovative

To activate it, must be kneed together with fingers quite a bit; it takes 15-25 minutes to set and cures in 1 hour, with a light tan color ending, repairing and restoring at the very first time. For use on exterior or interior applications, it contains no solvents, will not rot, shrink, crack or pull away.

The problems

You should only cut as much as you’ll use within 5-10 minutes because it will become less pliable over time, as it is an epoxy putty. In addition, you need to mix it thoroughly for about 2-3 minutes, with the correct mixing ratio. It will paint like wood but the stain doesn’t soak in.

Pros

- Nice color ending

- Ultra-fast dry

- It integrates with the repair

- Will not crack or shrink

Cons

- A little uncomfortable to knead and apply

- 2 years shelf-lif

- Not stainable

How to Choose the Right Wood Glue

In order to choose the best wood glue, you have to consider what the function of the adhesive is going to be. When you need a glue that will provide maximum strength or versatility there are some excellent products on the market, but if ease-of-use and speed are what you want then Gorilla Wood Glue might just be your best bet. Regardless of which one is used, care needs to be taken when gluing any type of wood depending upon whether it’s hardwood or softwood in order for things like water damage not to take place.

White Glue vs Yellow Glue

White glue can be used for a variety of projects, from attaching paper to furniture; assembling simple wooden objects and most crafts. White glue is an economical product that will work in many situations when yellow glue isn’t feasible like woodworking projects because it readily dissolves in water. So use white glue on porous surfaces where the more powerful yellow glues can cause damage.

Yellow Wood Glue

Specialty applications require specialty products like yellow wood glues which are made specifically for certain types of surface adhesion needs. As a result, they have very specific properties: some offer maximum strength or versatility. If you’re using hardwoods or softwoods, be sure to use the best wood glue for the type of wood that’s being worked on.

Yellow glues are used as a construction adhesive for joining pieces of plywood, particleboards, and similar materials together. It can also be used with MDF board when making face frames or furniture where strength is necessary.

How to Apply Glue To Wood?

The best glue for furniture repair jobs depends largely on what type of project you have in mind. While some items like end tables, wooden bowls, kitchen cabinet doors, and lawn chairs require an old-fashioned hammer and nail method; other projects may require more modern techniques such as adhesives–glues which will provide easy application without having to worry about things projecting over an edge.

Wood Glues Types Depending on the type of wood you’re using for a project, there are different types of glue that can be used: Yellow, white, or polyurethane glues: These glues work well with any type of wood.

- Epoxy adhesives: This type of adhesive is made to adhere metal and plastic together and they’re usually not the best choice for woodworking projects due to their high cost.

- Cyanoacrylate (CA, instant glue): It’s easy to apply, quick-drying but its hold isn’t very strong; therefore it’s great for small jobs like repairing furniture cracks where high strength isn’t needed. Globally, this adhesive is known as the “Super Glue.” Polyvinyl acetate (PVA): This type of glue is white or yellowish and water-soluble. It has a long working time, but it’s not suitable for use on oily surfaces.

- Lumber glues: LUMBER GLUES are used for constructing furniture from wood. Different from other adhesives, this formula contains resin that allows the wood to expand and contract with seasonal changes in humidity without cracking or breaking apart.

- Proprietary glue: Some manufacturers provide their own brands of these products along with instructions; they’re made specifically for certain types of projects and you need to follow instructions carefully while using them if you want to obtain the best results possible.

Tips for Using Wood Glue

When using wood glue, there is one important thing to remember: most wood glues have a shelf life of 12-18 months and will stop being effective after this time. So be sure to look at the expiration date on your wood glue before you purchase it and make sure you use it up before the deadline. Your local home improvement store will have a variety of different types and brands to choose from, so be sure to pick the one that works best for your project.

If you’re using wood glue for furniture repair work, there are some special tips to keep in mind if you want your end result to hold up: First off, remember that wood glue has its own unique smell which is very similar to vinegar, so take care not breathe it in too deeply! Secondly, make sure the surface is clean and dry before applying any type of wood glue product.

Most wood glues come with their own distinct nozzle design to help provide maximum precision when applying them. Some nozzles spray out like a stream; others squirt out like a small dot or even a thicker line of glue, and some are made to apply it like you would with a paintbrush.

Glue manufacturers will also provide instructions for how to apply their product; however, here are general tips for using wood glue:

- Wood Glues are always applied in two parts: the base coat (or primer) which is painted onto the surface first, and then the top layer which hardens over the base coat when dry. The top layer can be either thick or thin depending on what your specific project needs dictate.

- You will need to sand down your surfaces before applying any wood glue so that it adheres well.

- For small jobs like furniture repair jobs, where precision is more important than strength, use the thick top layer of wood glue.

- For larger projects where strength is important as well, use a thicker base coat with a thinner top layer to ensure that both layers bond together properly.

- If you need to apply the same type of wood glue more than once to get it to adhere properly, be sure to let it dry for at least 12 hours between applications so that it can fully cure.

To determine whether or not your adhesive will work best for various projects here’s an easy formula: Take 20% off your project size and then add 5% for each material thickness. For example, if your furniture repair job measures 24″ x 48″ (3/4 inch thickness), the surface area would be 30 square feet. Take 20% off that which means you’d use 12 square feet of wood glue mixture (24 3/4) . That equals 4.8 gallons. The formula will always leave you with a round number so at no point do you have to worry about cutting your total by fractions.

Hide glue is the all-natural choice for wood furniture repair

Hide glue is the natural choice for wood furniture repair, which is made from animal skin and bones. The glue sets in about an hour or so after application. Hide glue is often used on guitar and violin stringed instruments because of its rigidity, strength, and ability to hold up to changes in climate. It’s also great for larger projects that need to last a long time because it dries quickly.

What to Consider When Choosing the Best Wood Glue

There are several different types of wood glues that you may come across as you shop around. Here is a quick overview:

White glue (sometimes called school glue) is ideal for projects with small pieces because it dries very quickly and tends to be rather weak. It’s great for kids’ crafts and other short-term projects where strength isn’t an issue. This type of wood glue holds best on porous surfaces or when applied in thick layers.

Yellow or “school grade” wood glue is still made from animal skin, but it has been treated so that it no longer smells bad like white glue does. In fact, this type of odorless product makes for a great all-purpose choice for any wood furniture repair project, including larger ones when the strength is more important than precision.

Yellow glue can also be used on nonporous surfaces and dries in an hour or less depending on how thick you apply it. It will dry hard enough for use within 24 hours of application.

PVA (polyvinyl acetate) glues are multi-purpose and have just about replaced yellow wood glues because they are so versatile; however, they still don’t work as well with porous surfaces like unfinished oak. PVA works best with finished woods and other types of non-porous finishes as well as other materials like paper, fabric, leather, even gum! This type of high-quality product has a tendency to outlast wood glue and can be painted, stained, or even varnished over afterward for a professional finish.

Acrylic glues are extremely popular as well because they can be used on practically anything due to their versatility. They work especially well with porous surfaces and can often be used on finished pieces of wood without affecting the appearance of the surface when it’s dry. This type of wood glue is completely water-soluble and is very easy to clean up with warm water; however, it does need to be used in thick layers like PVA or yellow glues do so that it doesn’t crack when applied.

Epoxy resin adhesives are stronger than all of the others listed here and are more likely to be used for heavy-duty projects. They’re extremely popular in commercial construction or for crafts that are made out of scrap wood such as a picnic table, toolbox, and even bulletin boards. Epoxy resin adhesives have the best overall strength compared to all other types on this list; however, they can be very difficult to set and often need to be mixed carefully in an area that’s free of dust or other contaminants so that the joints can bond properly.

Epoxy resin adhesives are clear when they dry, but you may want to tint them with colors like red or blue for a fun and interesting look. You will definitely need special tools for use with epoxy glues, including a mixing tray in addition to the tubes. There are also special formulas that you can purchase by gallon for even larger projects.

FAQs About Wood Glue

CONCLUSION

When it comes to glue for furniture repair, there are many different types and formulas that offer various benefits. The best wood glue for your needs will depend on the type of project you’re working on as well as what surfaces need affixing together. Whether you prefer a PVA adhesive or an epoxy resin adhesive, make sure you purchase from a trusted brand like Gorilla Glue® which has been in business since 1937! We hope these tips have helped!

In this review, we have combined classic products from leading brands such as Elmer’s Products, Gorilla, or Titebond with other innovative applications of wood glue.

Gorilla Wood Glue or Titebond III maybe your options to consider if your interest is in exceptional strength and toughness, while Inc Elmer’s or Titebond II may be great choices if you are looking for decent quality for a moderate price.

If what you need is a perfect finish that integrates well with your repair, we would certainly go for the KwikWood product. In any case, our recommendation is that you analyze well the conditions to which you are going to submit the final product and look for a characteristic that allows that environment in our overviews.