Durability. Dovetail drawers are known for their durability. The joint’s design provides exceptional resistance to the stresses of heavy items, making them ideal for storing dishes, pots, and pans. The construction of dovetail drawers ensures that they will not come apart easily, even with frequent use.

What are the advantages of sliding dovetails?

The sliding dovetail joint has a number of advantages: it’s mechanically strong, provides a decent amount of glue surface, is reasonably easy to machine and is attractive when assembled. You don’t need a whole lot of fancy tools to create it, just a router, router table and a dovetail bit.

Is dovetail the highest quality?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint.

What is the advantage of dovetail joint?

The advantages of the dovetail joint are that it is the strongest of all joints, has a large gluing area, is interlocking, resists being pulled apart, looks attractive, and would hold together even without glue.

When did furniture makers stop using dovetail?

By 1730, through dovetail joinery was abandoned in English furniture making in favor of the lapped construction. As furniture became more refined, furniture makers began to take pride in the construction of their drawers as well.

What are the pros and cons of a dovetail joint?

The interlocking dovetail joint has a large gluing area, further adding to its strength. Hand cut dovetail joints require precise handsaw and chisel skills, and can be fiddly to mark out and cut. If dovetail joints are poorly made they will lose the advantage of strength and durability.

How important are dovetail drawers?

Making sure that you pick a drawer joint that can withstand this type of wear and tear is crucial to the longevity of your kitchen cabinets. Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

Are dovetail drawers worth it?

Dovetail drawers are known for their durability. The joint’s design provides exceptional resistance to the stresses of heavy items, making them ideal for storing dishes, pots, and pans. The construction of dovetail drawers ensures that they will not come apart easily, even with frequent use.

What is the best joinery for drawers?

Dovetail joints are without a doubt the king of drawer joinery. This venerated method has proven its mettle over the centuries and, for many people, represents the pinnacle of craftsmanship.

What is the best joint for a drawer?

Due to its superior strength and simple design, the mortise and tenon joint has been used for centuries. Typically used to join two pieces of wood at a 90 degree angle, this joint is especially common in drawer construction.

What is a dovetail drawer?

Dovetail drawer boxes are usually made out of a solid hardwood like Ash or Maple. The joints at the front and back of the drawer boxes are notched to fit together like a puzzle piece. This adds extreme strength to the drawer box joints.

What is the weakest wood joint?

A butt joint is the easiest of all simple wood joints, but also is the weakest. The cut end of one board butts up against the edge of another piece at a right angle. The key to every type of wood joint is having smooth, square cuts on the boards, and the butt joint is no exception.

What is the significance of dovetail?

The dovetail design is an important method of distinguishing various periods of furniture. The etymology of the name comes from the resemblance between the tenon or mortise of the joint to the shape of a dove’s tail .

What furniture should not be refinished?

Some furniture is not worth refinishing. If your furniture is constructed from particleboard, veneer over plywood or even Medium Density Fiberboard (MDF), refinishing it will be a waste of time and resources. Less expensive furniture made in the last three or four decades is often made from these materials.

Are dovetail joints glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

Is a sliding dovetail strong?

Also known as a through housed dovetail joint, a sliding dovetail joint is a strong, mechanically locking way of joining boards cross-grain.

Why is the dovetail slide widely used in engineering?

“A dovetail slide is used more for positioning, usually not high cycling,” said Dale Blank, Engineering Supervisor at Gilman Precision. “A dovetail slide is easier to lock up because of the angles on the dovetail. If you want to position something and lock it tight, a dovetail would be a good fit for that application.”

What is the definition of sliding dovetail?

Sliding dovetail Sliding dovetails are assembled by sliding the tail into the socket. It is common to slightly taper the socket, making it slightly tighter towards the rear of the joint, so that the two components can be slid together easily but the joint becomes tighter as the finished position is reached.

What is a dovetail on a slide?

Dovetail slides may also be called dovetail way slides. They are composed of a flaring tenon or saddle (moving member) and a mortise (fixed base) into which the tenon interlocks, yet can slide. Dovetail slides are direct contact systems where the sliding area is considered the bearing system of the dovetail slide.

Where is the dovetail joint most suitable to be used?

The pins and tails fit together in a way that interlocks naturally and effectively, preventing separation. A variety of wooden furniture and many other wood crafts utilize the dovetail joint, such as chests, cabinets, drawers, cupboards, jewelry boxes, tables, partitions, frames and even wooden instruments.

What are the 2 types of dovetail joints?

Types of Dovetail Joints Half-Blind dovetails: In these, the pins and tails are hidden. Half-blind dovetails are only revealed when moved, opened or seen from a certain angle, like behind a drawer face. In a through dovetail, both the dovetails and pins are visible.

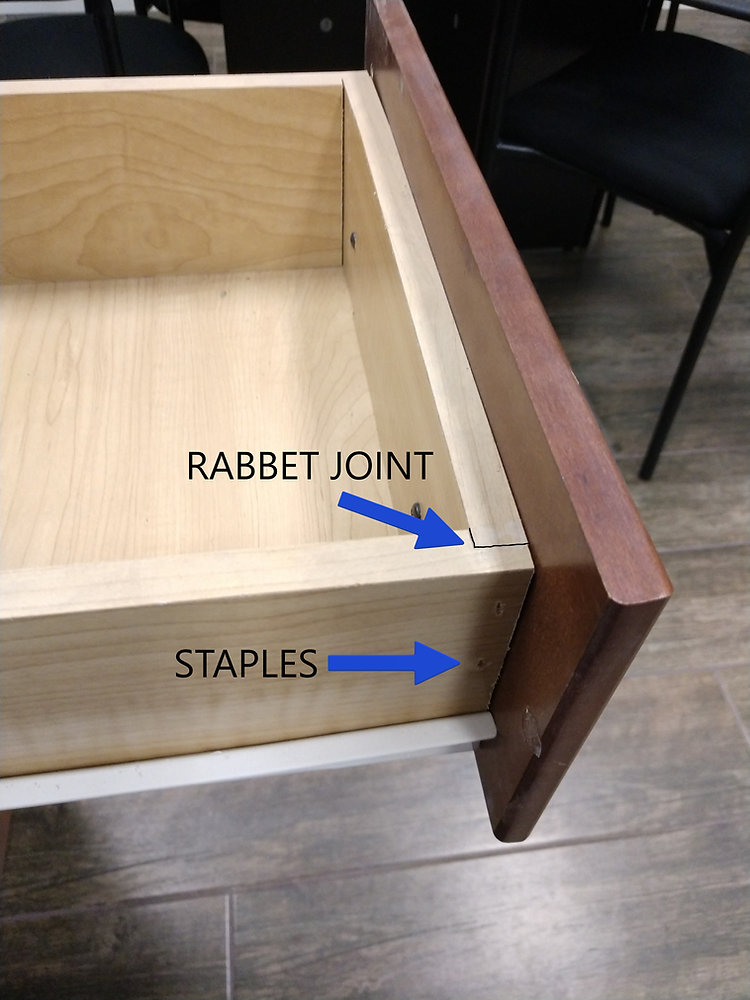

What can I use instead of a dovetail drawer?

To build a drawer without dovetails the most durable way is to use dowels. Other options include dado joints, rabbet joints, or reinforced butt joints.

What is the best material for dovetail drawers?

If you want high-quality drawers that will last you a long time, dovetail joints are the way to go. This style will work with almost any kind of wood, but typically, birch is the least expensive wood option. Keep in mind that once you select your dovetail drawers, you probably will be using them forever!

Can you make dovetail drawers with plywood?

A wide variety of methods can be used to make dovetail plywood drawer boxes. They are generally considered by the woodworking industry as time-consuming and difficult to make. The dovetails can be cut by hand with a dovetailing saw and chisel or you can use a dovetail jig and router.

Which is stronger box joint or dovetail?

For this test, the box joint proved stronger. Plus, the box joint is strong in both directions, whereas the dovetails are useful only for pulling from one piece, but not the other. So really, to use a dovetail joint for the sake of strength is obsolete, mostly on account of the strength of wood glues.