There should be roughly one dovetail each 25mm or so across the width. There’s no hard and fast rule so it’s up to the woodworker to use his or her judgement to decide how many are needed. The wood here is 92mm wide and as a consequence I’m going to have three dovetails.

How big should dovetails be?

For drawers, boxes or trays 2″ or less I generally like a single dovetail. For 3″ to 3 1/2″ and less two dovetails, for 4″ three dovetails, for 5″ to 6″ four dovetails and for 6″ four or possibly five.

What are the common dovetail sizes?

What size dovetail chisels do you really need?

Chisel Sizes – – 12mm / 1/2″ – This will do the majority of your morticing, and come in when cleaning out the pins on those dovetails. – 19mm / 3/4″ (or above) – A nice wide chisel is very useful, and I’d probably aim at an inch, though somewhere between 3/4″ – 1 1/4″ will fit the bill.

How do you dimension a dovetail?

To obtain dimension x for measuring male dovetails, add 1 to the cotangent of one-half the dovetail angle α, multiply by diameter D of the rods used, and add the product to dimension α.

How big should dovetails be?

For drawers, boxes or trays 2″ or less I generally like a single dovetail. For 3″ to 3 1/2″ and less two dovetails, for 4″ three dovetails, for 5″ to 6″ four dovetails and for 6″ four or possibly five.

Are 3 8 and 11mm dovetail the same?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

What are the rules for a dovetail joint?

The general rule is that they measure half the thickness of timber plus around 1 mm along the shoulder line. So these two awl dots are 7 mm in from each edge. These two dots, which mark the corners of the half pins, are now converted into a 1:8 slope at each side.

Is dovetail 11mm?

The standard 22 tip-off dovetail in the US is 3/8″ at the bottom and up to 1/2″ at the top. The European 11mm dovetail is typically 11mm at the top and perhaps 8mm at the bottom. The 11mm dovetail typically has a 60 degree angle from the bottom inside corner to the top where the 3/8″ is typically 45 degrees.

What is the most popular dovetail joint?

Single-lap Dovetail The single-lap (known to many folks as a half-blind dovetail) is the best known of the dovetails since it’s used to join the front to the sides of a drawer.

What is a standard dovetail?

A series of pins cut to extend from the end of one board interlock with a series of ‘tails’ cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

What is the most common dovetail ratio?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

Are dovetail chisels worth it?

The triangular cross-section of these chisels make them ideal for paring and chopping away the waste on dovetail joinery. Suitable for other joinery tasks, these affordable chisels are a nice complement to standard bench chisels for creating and fine-tuning joinery.

Which chisel is best for dovetails?

Fishtail Chisels are perfect for reaching the back corners of half-blind dovetails and paring other hard-to-reach areas. Their unique shape offers versatility for right and left hand recesses.

How tight should dovetails be?

If you can use your fist as a hammer to nudge them together, they’re just right. By the way, when you realize they will fit nice and snug, (hopefully by the time they are less than half way down) take them apart and don’t put them together again until you glue them.

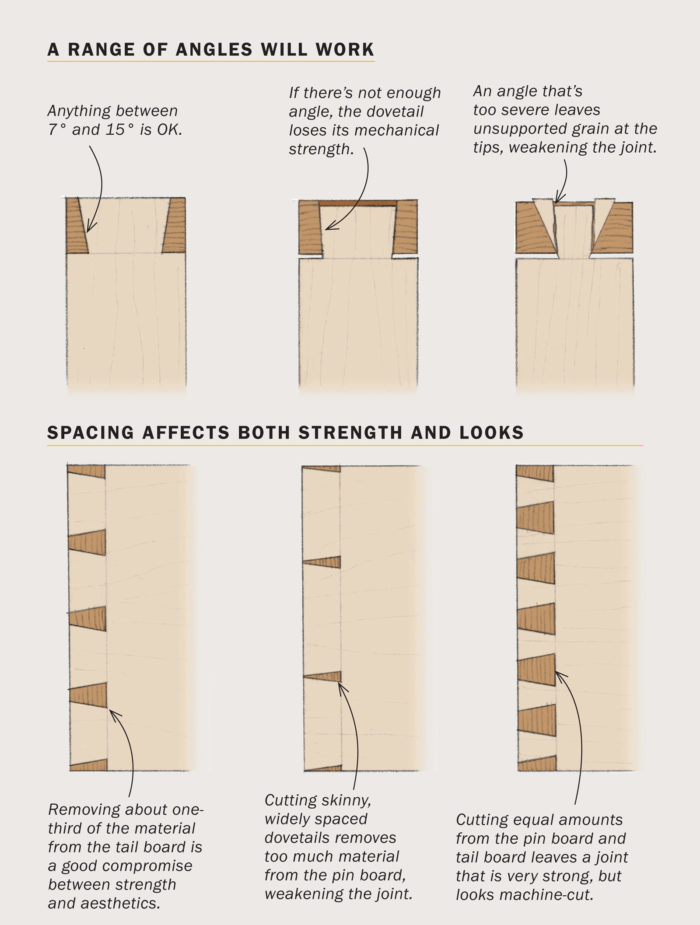

What angle do you cut dovetails?

Lower (7° to 9°) angles are often advised for joining hardwoods, while higher angles (10° to 14°) are recommended for softwoods and even higher angles (14° to 18°) for half-blind dovetails.

What is the common dovetail ratio?

Anything from 1:6 to 1:9 looks good and works well. Too little rise leaves corners with short grain that easily breaks off, too much rise looks like a poorly made box joint.

How deep should dovetails be?

For example, if the gable of a chest of drawers is 3/4″ thick, machine the dovetail groove between 1/4″ and 3/8″ deep. Any deeper and you will weaken the gable too much.

What is a standard dovetail?

A series of pins cut to extend from the end of one board interlock with a series of ‘tails’ cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

How thick should a dovetail jig be?

Dovetail Jig rave about the user-friendly features. The jig’s patented alignment lines and router bit-depth stop simplify set up and get you up and running in no time. This versatile jig accepts stock from 1/4 to 1-1/8 inch in thickness and up to 12 inches in width.

How big should dovetails be?

For drawers, boxes or trays 2″ or less I generally like a single dovetail. For 3″ to 3 1/2″ and less two dovetails, for 4″ three dovetails, for 5″ to 6″ four dovetails and for 6″ four or possibly five.

What rifles have 11mm dovetail?

Is dovetail the strongest joint?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

Is dovetail the highest quality?

Dovetail drawers are considered a sign of quality, a hallmark of solid construction, and are generally recommended for anyone in the market for cabinets.

Should dovetail joints be glued?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

What is the weakness of dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.