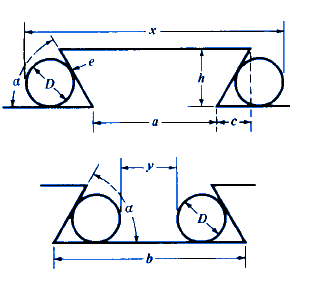

To obtain dimension x for measuring male dovetails, add 1 to the cotangent of one-half the dovetail angle α, multiply by diameter D of the rods used, and add the product to dimension α.To obtain dimension x for measuring male dovetails, add 1 to the cotangent of one-half the dovetail angle α, multiply by diameter D of the rods used, and add the product to dimension α. x = D (1 + cot 1/2 α) + a c = h · cot α

How do you calculate dovetail joints?

How are dovetail cutters measured?

Overall length of dovetail router cutters The overall length of a cutter is measured from the top of the shank to the bottom of the cutting edges or guide (if there is one). Dovetail cutters range in length from 52mm (2″ approx.) to 80mm (3¼” approx.)

How do you mark out dovetails?

Mark out the two ‘half-pins’ at the edges on the first piece of wood. The ‘pins’ are the bits of wood between the tails so there are two half-pins; one each side. The general rule is that they measure half the thickness of timber plus around a mm, so the two dots on the shoulder line are 7mm in from each edge.

What is the ratio for dovetails?

Dovetail angles are usually expressed as ratios — the most common being 1:6 and 1:8 (said “one in eight,” and also written as 6:1 or 8:1). As a general rule of thumb: Use 1:6 for softwoods. Use 1:8 for hardwoods.

How do you mark out dovetails?

Mark out the two ‘half-pins’ at the edges on the first piece of wood. The ‘pins’ are the bits of wood between the tails so there are two half-pins; one each side. The general rule is that they measure half the thickness of timber plus around a mm, so the two dots on the shoulder line are 7mm in from each edge.

What size dovetail should I use?

We recommend dovetail width should not be less than 75% of the width of the stock. This is a general ratio, not a rule. If in doubt, stick to 75%. Dovetail width should be narrow enough to support the part after material is removed.

Are 3 8 and 11mm dovetail the same?

However, that is not the only difference between the two dovetails. They also have different groove angles as shown below. The 11 mm dovetail has a 60-degree angle, while the 3/8” dovetail has a 45-degree angle.

What is the standard angle for a dovetail?

Answer from the experts: Clearly, there’s no shortage of advice about the “best” dovetail angle: Some woodworkers recommend using 12° for “coarse work” and 7° to 10° for decorative joints.

What is a standard dovetail?

A series of pins cut to extend from the end of one board interlock with a series of ‘tails’ cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

What are typical dovetail angles?

Although softwoods are more compressible than hardwoods, you needn’t change the dovetail angle to add strength to the joint. Any angle between 7° and 15° will work, regardless of the wood. But stay within that range. If you go below 7°, you’ll start to lose the mechanical strength of the dovetail.

How does a dovetail template work?

Each template will use specific router bits, to cut dovetails on one side, and pins on the other side. Joined together, the two pieces form a dovetail joint that is strong and durable. When you follow a few simple instructions, a dovetail jig should deliver precise joints every time.

What tool for marking dovetail joints?

For quick, accurate marking of dovetails, a dovetail marker is the best tool available. With riding ledges on both sides, these 2″ × 2″ markers can be flipped over to mark both slopes of the dovetail. They are designed so that the entire ledge is riding on the reference face, even when marking edge dovetails.

What is a 6 to 1 dovetail?

A 1:6 ratio – that’s one unit horizontal with six matching units drawn vertical – lays out as a 9.5 degree angle.

What ratio is a 14 degree dovetail?

There is no hard and fast rule when it comes to dovetail angles. Commonly accepted ratios are 1:8 for hardwoods and 1:6 for softer timber. This 14° marker equates to a ratio of 1:4.

Are dovetails the strongest of all joints?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

What are the rules for dovetail design?

As a rule of thumb the dovetail’s maximum width should occupy approximately 1/ 2 to 3/ 4 of the gasket’s width (leaving a 1/ 4 – 1/ 8 of gasket width on each side). For larger gasket widths, multiple dovetails can be made side-by- side, facing the same direction or inverted.

What is the formula for the angle of the internal dovetail?

Explanation: Formula for finding the angle of an internal dovetail is Tan A = (l2-l1/2) / h where l1 and l2 are the distance across the pins and h is the height of slip gauges. Thus by knowing these three parameters, angle A can be calculated.

What is the ratio for 14 degree dovetail?

There is no hard and fast rule when it comes to dovetail angles. Commonly accepted ratios are 1:8 for hardwoods and 1:6 for softer timber. This 14° marker equates to a ratio of 1:4.

How does a dovetail template work?

Each template will use specific router bits, to cut dovetails on one side, and pins on the other side. Joined together, the two pieces form a dovetail joint that is strong and durable. When you follow a few simple instructions, a dovetail jig should deliver precise joints every time.

How do you mark out dovetails?

Mark out the two ‘half-pins’ at the edges on the first piece of wood. The ‘pins’ are the bits of wood between the tails so there are two half-pins; one each side. The general rule is that they measure half the thickness of timber plus around a mm, so the two dots on the shoulder line are 7mm in from each edge.

What is the most popular dovetail joint?

Single-lap Dovetail The single-lap (known to many folks as a half-blind dovetail) is the best known of the dovetails since it’s used to join the front to the sides of a drawer.

What is the minimum thickness for a dovetail?

Structurally I have looked for pin strength in dovetails as the dovetailed aspect is always strong because it is always at least as wide and mostly wider than the pins. In my own work I aim for a minimum size of 1/4″ and mostly 3/8″.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

What is the most common dovetail ratio?

With regard to what to use, a common recommendation is 1:8 for hardwoods and 1:6 for softwoods. These recommendations are based on some arguments related to strength. However, people use a lot of different ratios depending on application and aesthetics.

Is dovetail the highest quality?

Without a doubt, dovetail joints are revered as one of the strongest woodworking joints. The strength lies in the precise shaping of the tails and pins. When these elements fit snugly together and are bonded with glue, the resulting joint becomes nearly impossible to pull apart.