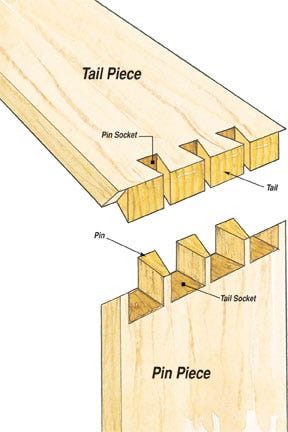

A series of pins cut to extend from the end of one board interlock with a series of ‘tails’ cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners.

What are dovetails used for?

A dovetail joint is a joinery technique used in woodworking, traditionally used to join wooden furniture. Dovetail joints are known for their inherent strength and resistance to being pulled apart (tensile strength).

What is a dovetail marker used for?

For quick, accurate marking of dovetails, a dovetail marker is the best tool available. With riding ledges on both sides, these 2″ × 2″ markers can be flipped over to mark both slopes of the dovetail. They are designed so that the entire ledge is riding on the reference face, even when marking edge dovetails.

Why do people use dovetail joints?

A dovetail joint is a joinery technique used in woodworking, traditionally used to joint wooden furniture. Dovetail joints are known for their inherent strength and resistance to being pulled apart (tensile strength).

What is the purpose of a dovetail jig?

The dovetail jig helps the woodworker to easily make dovetail or finger joints when constructing boxes and furniture items. It’s only limited by your imagination. Dovetail jigs, in particular, come in different forms.

Do they still use dovetail joints?

Dovetail joints used to be the best way to join pieces of wood, especially a box or drawer. I used to cut them by hand but now you can buy jigs. Modern glues, like Gorilla Glue, are so strong I rarely use a dovetail joint unless it’s going to show. I usually use a rabbet, or sometimes even a butt joint.

What are the disadvantages of a dovetail joint?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

What is the difference between dovetail pins and tails?

They’re comprised of interlocking wedge-shaped components: the tails and the pins. To tell the difference, look at the sides of the components. The edges of the tails are square to a board’s face (and look like a dove’s tail), while the pins are angled to the board’s face (they look more like end grain trapezoids).

Are dovetails necessary?

What makes the dovetail joint so important for cabinet drawer construction is its resistance to being pulled apart. The interlocking pieces create a strong joint with just the quality wood. This joint is made even stronger with glue. The front-to-side joints take the bulk of a strain on a cabinet drawer.

When did they stop using dovetail?

According to oldcopper.org, coppersmiths kept on dovetailing the seams until about 1900, after which better joinery technology made the time-consuming dovetail process obsolete. This means that a dovetailed pot or pan could have been hand-cut or machine-cut.

What does a dovetail joint look like?

Although there are many different types of dovetail joints, all of them have the same pair of defining features. The first is the tail and the second is the pin. One piece of wood has a series of cuts to make angled, wedge-shaped edges. These are called tails because the shape resembles that of a dove’s tail.

How do you mark out a dovetail joint?

Mark out the two ‘half-pins’ at the edges on the first piece of wood. The ‘pins’ are the bits of wood between the tails so there are two half-pins; one each side. The general rule is that they measure half the thickness of timber plus around a mm, so the two dots on the shoulder line are 7mm in from each edge.

Do you need to glue dovetail joints?

Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

What are the advantages and disadvantages of a dovetail joint?

The interlocking dovetail joint has a large gluing area, further adding to its strength. Hand cut dovetail joints require precise handsaw and chisel skills, and can be fiddly to mark out and cut. If dovetail joints are poorly made they will lose the advantage of strength and durability.

What if the dovetail joint is too loose?

If the joint is too loose, lower the bit by the amount of looseness. If too tight, raise the bit by that amount. Flushness is adjusted by changing the position of the fingerboard. Tails should be recessed by 1/64″ or less.

Are dovetails necessary?

What makes the dovetail joint so important for cabinet drawer construction is its resistance to being pulled apart. The interlocking pieces create a strong joint with just the quality wood. This joint is made even stronger with glue. The front-to-side joints take the bulk of a strain on a cabinet drawer.

Are dovetails the strongest of all joints?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

When was dovetail used?

While dovetail joints can be found on ancient Egyptian coffins from 3000 BC, they were not used in European and American furniture until the mid 1600s.

Are dovetail joints worth it?

Making sure that you pick a drawer joint that can withstand this type of wear and tear is crucial to the longevity of your kitchen cabinets. Dovetail joints are considered one of the strongest joints used in kitchen cabinetry construction and are the best solution for a kitchen cabinet drawer box.

What are the rules for dovetail joints?

The space between half pins is divided between pins and tails. Fine work the pins 4mm > 6mm, larger work 7mm > 12mm. To have a desirable appearance the pins smaller than the tails. Your tails should be around 18mm > 35mm for fine work like drawers and 35mm > 55mm on larger work like a chest.

Are dovetails the strongest of all joints?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

What is the weakest wood joint?

A butt joint uses a simple technique whereby two pieces of material are joined together at their ends, without any special shaping or cutting. Although it is simple, the butt joint is also the weakest of the wood joinery types.

What is the strongest wood joint?

Mortise and tenon joints are widely regarded as one of the strongest and most reliable woodworking joints. They involve creating a mortise, or a hole, in one piece of wood and a tenon on the end of the other piece, which fits into the mortise.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

How many pins are in a dovetail joint?

There is usually a three pin setup but more or less pins can be used depending on how much strength and aesthetics you want.

What is a French dovetail joint?

Fyi, the English dovetail technique is also commonly referred to as a butt joint. French Dovetail: This technique is based on cutting out a slat in the middle of a board and also a corresponding piece of wood that can slide into the middle cutout. English and French Dovetail Drawer Construction.