Michael Dresdner: The only areas that require glue on dovetails are the diagonal faces. All the diagonal faces are long grain, all the square faces are end grain, and all the flat faces abut end grain. Therefore, you need only apply glue to the diagonal faces on the tails or pins, or both.

What glue to use on dovetails?

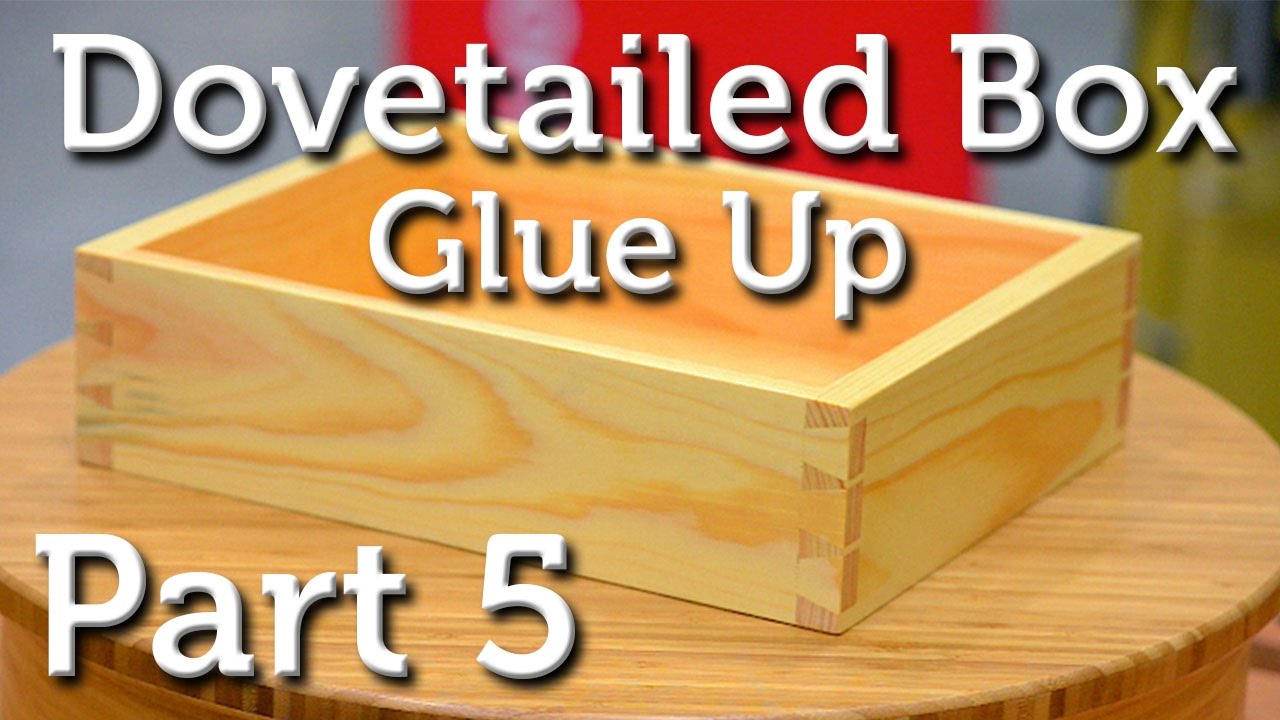

My preference is to glue up dovetails with traditional, hot hide glue. I use it only on the flat grain surfaces, and a bit sparingly. You will need to work quickly.

Do you need to clamp dovetails?

Well cut dovetails don’t need clamps, but it’s always nice to have clamps and cauls laid out just in case. I also like to have a piece of wood slightly thinner than my tails to use to tap the tails together to make sure they are fully seated. Before walking away, I check the case for square, then let the glue sit.

What are the rules for dovetail joints?

The general rule is that they measure half the thickness of timber plus around 1 mm along the shoulder line. So these two awl dots are 7 mm in from each edge. These two dots, which mark the corners of the half pins, are now converted into a 1:8 slope at each side.

Is dovetail joint permanent?

The strongest and most permanent right-angled joints made in wood are the ‘dove-tail’ joints, as illustrated below. The so-called tails and pins fit together to form a secure joint.

How tight should dovetails be?

If you can use your fist as a hammer to nudge them together, they’re just right. By the way, when you realize they will fit nice and snug, (hopefully by the time they are less than half way down) take them apart and don’t put them together again until you glue them.

Can I use wood glue on twine?

Now that you’ve wrapped the twine, take the wood glue and brush it over the twine. This will keep the shape in place. Wait 24 hours for the glue to dry completely. Once the glue is dry, the twine should stay in the shape of the sphere.

Why are dovetail joints bad?

The disadvantages of dovetail joints are that they can be fairly difficult to mark out and cut, and if they are made badly these joints lose the advantages listed above. Depending on the project, function, and design, there are a number of different types of dovetail joints to choose from.

Why are dovetails so hard?

The dovetail joint is very strong because of the way the ‘tails’ and ‘pins’ are shaped. This makes it difficult to pull the joint apart and virtually impossible when glue is added.

Is dovetail worth it?

In addition to their durability, dovetail drawers are also incredibly strong. The interlocking pins and tails create a sturdy structure that resists twisting and warping over time. This means that your drawers will continue to work smoothly for years to come, without any binding or sticking.

Is a dovetail joint strong or weak?

Dovetail joints are known for their inherent strength and resistance to being pulled apart (tensile strength).

Are dovetail joints difficult?

This is a relatively complex joint that takes time to fit together. But it’s absolutely within the capabilities of anyone who knows how to use a hand saw. In my opinion, the hardest part is cutting the sides of the pins and tails accurately. Luckily, this is made a lot easier with a good dovetail jig.

How hard is it to make a dovetail joint?

Hand-cutting a dovetail joint is kind of a woodworking high-wire act; one slip of the saw or chisel and the joint either won’t fit together or will look sloppy. It takes a lot of time to master the ability to cut dovetails quickly and well (by hand or machine), without a lot of fussing around.

What is the strongest wood joint?

Mortise and tenon joints have stood the test of time for their remarkable strength. This traditional joint involves a projecting piece of wood, called a tenon, securely fitting into a corresponding cavity, a mortise. It can be reinforced with glue or wedges for stability for a stronger hold.

Which is better English or French dovetail?

While both English and French dovetail construction are very sturdy and high quality, English dovetail construction is slightly sturdier with the trade-off of being more expensive and time-consuming to produce.

Is a finger joint stronger than a dovetail joint?

For box joint, some people put a lot more fingers than it is possible to do with Dovetail. In this case, the gluing surface is larger, and the joint is likely stronger. Also, some find a way to hide a finish nail in the joint. Dovetail has the advantage of a mechanical lock independent of the glue.

What is the best way to glue a joint?

One good way to ensure a strong glue joint is to use the ‘rub joint’ method. Simply apply glue to the edges of one or both boards and rub them together to help spread the glue evenly before clamping.

What is the best glue for webbing?

Contact cement, an industrial-strength adhesive, can be used in many situations to glue nylon webbing and is generally strong enough to grip the nylon and the surface you’re adhering to. Contact cement should be applied to both surfaces you’re bonding together.

What is an impossible dovetail joint?

Press a dovetailed board into another board with matching sockets, and you’ve created woodworking’s most iconic joint. The dovetails and sockets wedge the boards together, so the joint can’t pull apart; the only way to disassemble it is to lift the dovetailed board back out of the sockets.

What is the ideal dovetail angle?

Percy Blandford, who has been writing about woodworking for a long time, writes in “The Woodworker’s Bible” that any angle between 7.5° and 10° is acceptable. The ideal, he says, is 8.5° for softwoods and 7.5° when joining hardwoods.

When should you not use wood glue?

If you’re trying to glue two pieces of wood that have significant gaps between them, wood glue is a poor choice, because it won’t span those gaps.

Will hot glue stick to rope?

From rope framing for a sign to tied knots glued to a wood slat to rope-embellished glass decor, the range of possibilities is extensive. To get the rope secure and to make it look beautiful, specialized glue or the use of a hot glue is a necessity.

Are dovetails the strongest joint?

Dovetail is arguably the strongest joint in millwork. It’s made so that it can’t be twisted or pulled in any direction except for one. This means that it’ll take more force to break or damage the joint. Because of the preciseness of each piece, this joint is held into place without the need for extra reinforcement.

When did they stop using dovetail?

By 1730, through dovetail joinery was abandoned in English furniture making in favor of the lapped construction. As furniture became more refined, furniture makers began to take pride in the construction of their drawers as well.

Do they still use dovetail joints?

On the other hand, a hand cut dovetail joint has a finer, thinner look and generally is not perfectly spaced. Hand cut joints were commonly used in both European and early American made furniture and date back to the early Egyptian times. They are still used today by many experienced custom furniture makers.

What is the most difficult woodworking joint?

Found frequently on drawers, the dovetail joint is the Holy Grail of woodworking joints. The wedge-shaped pins and tails are cut on mating pieces which resist being pulled apart. The dovetail is beautiful and strong, but among the most difficult joints to execute.