If you are in charge of placing a concrete floor or installing an outdoor patio, then you may be wondering which adhesive to use. There are many different products on the market, and it can be hard to know what is best for your project. To help you make this decision, we have compiled some of the most common questions people ask when choosing an adhesive for their project and product reviews, and helpful tips!

What is the best adhesive for concrete?

There are many adhesives for concrete on the market. Some have been around longer than others and come with a higher price point, but they will work well if used correctly.

The best adhesive really depends on what you’re looking for in an adhesive. For example, some people prefer to use epoxies because they don’t require drying time and can be mixed up ahead of time so that it’s ready when needed; other people find epoxies to be too expensive and go instead with standard thin-set mortar which does not contain hazardous components (epoxy is made from two different chemicals). It may take some experimenting before you figure out exactly what type of product will suit your needs or make sense within any given budget

Types of adhesives for concrete

There are three different types of adhesives for concrete: thin-set mortar, epoxy, and polyurethane.

Thin-set mortar is the most common type in North America because it’s a “green” product and can be mixed up ahead of time to don’t have to wait around for it to dry before continuing your construction project.

Epoxies are colorless or transparent, but they also require drying time which may slow down progress on your worksite (but not as much as if you were using wet cement).

Polyurethanes usually come in either black or white; they’re less expensive than epoxy but may take longer to set compared to other products.

Top 5 Adhesives for concrete

Loctite PL 500 Construction Adhesive

Have you been looking for the best adhesives to bond large construction projects together? Look no further than Loctite PL 500 Construction Adhesive.

From repairing leaky plumbing pipes during cold winters to building flyovers in hot summers – this adhesive is good for all-weather bonding. It’s strong, and it won’t give up like other products! It works well on a majority of surfaces, whether in humid, cold or even hot conditions.

This glue will make you wonder why you’ve been using anything else up until now!

Gorilla Construction Adhesive

Gorilla is a versatile adhesive used all year round to bond large construction projects together. It’s strong and won’t give up like other products. Works well on a majority of surfaces. This glue will make you wonder why you’ve been using anything else up until now!

Pros:

- This adhesive is strong, and it won’t give up like other products!

- It can be used in humid, cold, or even hot conditions. This glue will make you wonder why you’ve been using anything else up until now!

LIQUID NAILS LN-2000 Construction Adhesive

When you’ve got an important job to do that can’t wait, LIQUID NAILS LN-2000 Construction Adhesive is a perfect choice. This fast-curing adhesive will have your project secured in no time. It’s easy to use thanks to its low odor and hassle-free setup times. Whether it be bonding plywood, cement board, or wood subflooring for flooring, there may not be a more versatile construction adhesive on the market than LN-2000 Adhesive!

This product is compatible with a wide range of materials including wood, metal, plastic, and fiberglass, so it’s perfect for contractors or DIYers.

It also has low VOC elements which make it safe when used indoors. Bonding time on this adhesive ranges as little as 15 seconds – it doesn’t get any quicker than that! All orders come in an easy-to-use bottle with a long nozzle that prevents clogging and lets you pour smoothly without waste.

PC Products 72561 LPC Concrete Adhesive

It’s no surprise that concrete suppliers see this product as the best adhesive for their jobs. It’s compliant with ASTM and works under a variety of temps! Bond time is within 20 minutes, making this adhesive extremely versatile. What does that mean for you? You can fix anything anywhere!

That’s why we’re so excited to introduce our new LPC adhesive that can be used for any type of construction project. With a working temperature range from 35 degrees Fahrenheit to 115 degrees Fahrenheit, it’ll hold up immediately as long as the surface is clean!

This versatile product is perfect for chimney flue liners, bridge supports, brickwork, and retaining walls, so get started today!

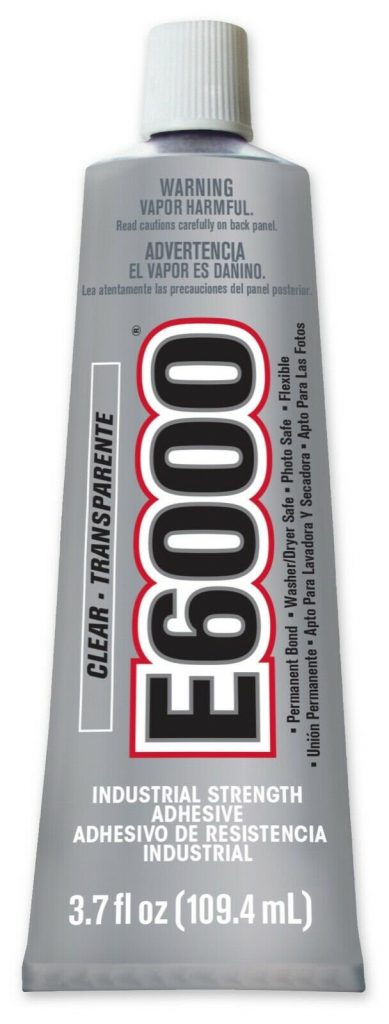

E6000 High-Viscosity Adhesive

Bonds better cures stronger and holds that much tighter- all while being safe for places other adhesives can’t touch. Whether you have to fill the small gaps between tiles or hold one object in place for dear life on a construction site, we’ve got your six with E6000 High Viscosity Adhesive. It’s tough and strong enough to handle an industrial project while flexible enough to work around delicate rocks without wearing them out.

Never worry about curing again because ours is fully instant thanks to its high viscosity formula and no icky chemicals used in the process! You’ll be able to tell when it’s ready by looking at the syringe’s finest detail followed by a slight yellowing as it dries.

It’s been extensively tested for compatibility with a wide range of materials, and it has excellent resistance to high-temperature conditions!

Comes in two sizes: Medium (11 oz) or Large (32oz).

Pros: Consistent adhesive that bonds better, cures stronger, and holds tighter all while being safe for places other adhesives can’t touch.

It’s tough and strong enough to handle an industrial project while flexible enough to work around delicate rocks without wearing them out.

Things to Consider When Buying Concrete Adhesive

When buying an adhesive for concrete, you’ll want to make sure that it’s compatible with the type of product you’re using. For example, if you use a self-leveling cement-like Stampede from Mapei, then polyurethane would be your best bet because epoxy and thin-set mortar are both too thick (using them would result in the Stampede coming out lumpy and uneven).

Another thing to consider is whether or not you want your adhesive to be waterproof. This may sound like a strange requirement, but some people only use an adhesive for concrete on sidewalks because they don’t need it to get wet (or stay wet)

Drying or cure time

Thin-set mortar is the fastest drying adhesive for concrete, coming in at about 12 hours. Epoxy takes 24 to 72 hours before it’s fully cured and ready to use.

Polyurethane can take up to 48 hours or more before it dries completely (and that time maybe even longer if you live in a humid area).

This is because polyurethane comes in two different versions: low-viscosity and high-viscosity. The “high” version goes on quicker, but it takes longer to dry than the “low.”

The best adhesive for your needs will depend largely on how much time you have and whether you need it to be waterproof or not.

Easy to use

Thin-set mortar is the easiest product of all three for beginners to use because it’s a “wet” adhesive. This means that you can apply it right away without waiting around for drying time (though there are some guidelines about how you should work with wet cement).

Epoxies require dry time, which may slow down your progress on-site if you need to wait 24 hours after applying before continuing your construction project. Polyurethanes usually come in either black or white; they’re less expensive than epoxy but may take longer to set compared to other products.

Floor size

Thin-set mortar is the cheapest solution for adhesives because you don’t need much of it to connect two pieces of concrete.

Epoxies are pricier than thin-set mortars, but they’re also more versatile because epoxy can be used in conjunction with other materials (such as metal), which cannot easily be glued together with concrete.

Polyurethane is the most expensive adhesive option because it’s very viscous and generally comes in larger containers than epoxy or thin-set mortar (which are both sold by weight).

Durability

Thin-set mortars and epoxies are both waterproof, so they’ll last for a long time.

Polyurethane is not waterproof, but it will stick to the concrete better than other adhesive options because it’s less likely to chip off or peel back (which can happen with thin-set mortar).

If you need your adhesive to be waterproof, then epoxy is the best option.

Easy to clean

Thin-set mortar is the easiest product of all three for beginners to use because it’s a “wet” adhesive. This means that you can apply it right away without waiting around for drying time (though there are some guidelines about how you should work with wet cement).

Low odor

Thin-set mortars and epoxies have a low odor, but polyurethane is often criticized for its strong smell.

There are many things to consider when buying a concrete adhesive because the needs of every person are different! Whether you need it to be waterproof or not, whether you want to wait 24 hours before continuing your project, and how much time you have before the project needs to be completed will dictate what kind of adhesive for concrete is best.

Epoxy tends to be more versatile than thin-set mortar because it’s less likely to chip off or peel back when applied properly (though epoxies are pricier).

Polyurethane is less expensive but takes longer to dry and cure properly. You’ll have the most choices with thin-set mortar, though it’s not perfect for waterproofing your project (epoxy is better).

If you need a quick-drying adhesive, then epoxies are best because they take at least 24 hours before they’re ready for use. In comparison, polyurethane will usually take 48 hours or more (though the wait time for epoxies may be longer if you live in a humid area).

Safe products

Thin-set mortar is the safest option for adhesives because it doesn’t contain any chemicals that could be hazardous to you or your project.

Epoxies and polyurethanes may both have various chemical components, so they’re less safe than thin-set mortars (though epoxy is usually preferred).

If you have kids or pets, epoxy is your safest option because it’s less likely to irritate polyurethanes.

If you’re using thin-set mortar as an adhesive for concrete and children in the home, make sure they wash their hands thoroughly after playing with any of the ingredients. This will prevent them from coming into contact with any potentially hazardous chemicals.

If you use epoxy or polyurethane, make sure to wear gloves and a mask (especially if there are children in the home).

Versatility

Thin-set mortars are the least versatile of all three adhesives because they’re only made to work with concrete and a few other materials.

Epoxies can be used in conjunction with many different types of substances, so epoxy is more versatile than thin-set mortar (though it’s pricier).

Polyurethane is the most versatile of all three because it can work with a wide range of substances that epoxy and thin-set mortar cannot.

Epoxy is better than other types of adhesives for concrete in some ways, but not others: It’s more expensive and takes longer to dry before you can use it (though the wait time may be shorter if you live in a humid area), but epoxy is the most durable and versatile.

Thin-set mortar is easy to use, cheap, and waterproof (though it’s not as durable or versatile).

Polyurethane is less expensive than other types of adhesives for concrete, though polyurethane also has a shorter shelf life and takes longer to dry before you can use it.

Advantages and disadvantages of each adhesive type

Thin-set mortar:

- easy to use

- waterproof – doesn’t cure as fast (24 hours before you can continue your project)

Epoxy:

- durable and versatile + less expensive than other adhesives for concrete – takes longer to dry and cure properly.

Polyurethane:

- the most versatile, able to work with many different substances that epoxy or thin-set mortars cannot + inexpensive – strong smell, short shelf life, shorter drying time.

- the most versatile, able to work with many different substances that epoxy or thin-set mortars cannot + inexpensive – strong smell, short shelf life, shorter drying time.

How to choose what’s right for you

The best adhesive for concrete really depends on what you’re looking for in an adhesive. For example, some people prefer to use epoxies because they don’t require drying time and can be mixed up ahead of time so that it’s ready when needed; other people find epoxies to be too expensive and go instead with standard thin-set mortar which does not contain hazardous components (epoxy is made from two different chemicals). It may take some experimenting before you figure out exactly what type of product will suit your needs or make sense within any given budget.

How to Use Concrete Adhesive

Epoxy and polyurethane are the two types of adhesive for concrete that you can use on your project.

Object (epoxy is better). If you need a quick-drying adhesive, then epoxies are best because they take at least 24 hours before they’re ready for use. In comparison, polyurethane will usually take 48 hours or more (though the wait time for epoxies may be longer if you live in a humid area).

If you have kids or pets, epoxy is your safest option because it’s less likely to irritate polyurethanes. If you’re using thin-set mortar as an adhesive for concrete and children in the home, make sure they wash their hands thoroughly after playing with any of the ingredients. This will prevent them from coming into contact with any potentially hazardous chemicals.

If you use epoxy or polyurethane, make sure to wear gloves and a mask (especially if there are children in the home).

Epoxies take longer than other types of adhesives for concrete to dry before they can be used on your project: Epoxies typically need 48 hours or more, while thin-set mortar only needs 24 hours.

It’s best not to mix an adhesive for concrete ahead of time because it may lose some effectiveness as time passes or react negatively when mixed; however, this isn’t always true depending on what type(s) of material you’re using, so it’s best to do a little research first.

If you’re using thin-set mortar, make sure that the surface is wet with water before spreading it around: this will help keep the mixture from drying too quickly and produce a smoother consistency when applied.

Mixing epoxy or polyurethane ahead of time can be helpful because they need 24 hours or more for proper curing; however, if you mix these two adhesives up ahead of time, then there are risks associated, such as them reacting negatively when mixed, so it may not always work out well (though sometimes it does). It would probably be better in most situations to wait until you actually need an adhesive for concrete before mixing either one.

Please keep all of your materials close together, so you don’t have to run around the house looking for them.

Frequently Asked Questions (FAQs)

Final thoughts on choosing an adhesive for your project

If you want to build a concrete project but don’t know what type of adhesive is best for the job, this article will help. We’ve gone over different types of adhesives and their pros and cons so that you can make an informed decision about your upcoming project. There are many factors to consider when choosing which kind of adhesive to use on any given project – not just durability! But our goal was to find one that would be good in all areas (adhesion, cohesion, abrasion resistance). Whether it’s epoxy or polyurethane, we hope we’ve been able to provide enough information for you to decide which one works best with your needs.